Industry news

Cable tray refers to a metal bracket used to carry wires and cables and hang them on the walls or ceilings of buildings. There are several requirements for the use of strong and weak current cable trays:1. Safety: Both strong and weak current cable trays need to meet corresponding safety standards

2025/11/11 13:37

Flame-retardant BV cables can be installed within fireproof cable trays. Flame-retardant BV cables are wires with flame-resistant properties that ensure safety under certain fire hazards. Fireproof cable trays are made of steel materials, offering high fire resistance and safety. During

2025/11/04 13:37

NB/T42037 is a standard for anti-corrosion cable trays, which specifies the models, requirements, inspection rules, markings, packaging, transportation, and storage of metal cable trays used for power system installation. This standard applies to cable trays used indoors and outdoors, as well as to

2025/10/30 13:37

Glass tempered bridge has certain flame retardant properties. Fiberglass reinforced concrete (GRC) bridge, also known as fiberglass reinforced concrete (FRP) bridge, is a type of bridge made of materials such as fiberglass, alkali resistant fiberglass, epoxy resin, etc. Its flame retardant

2025/10/30 13:37

Plastic steel cable tray is a common building structural material, mainly made of polyvinyl chloride (PVC) and fiberglass. It has excellent corrosion resistance and structural strength, and can withstand large loads. In addition, plastic steel cable trays have the characteristics of waterproofing,

2025/10/30 13:37

Trough type cable tray is a closed type of cable tray, usually used for laying electrical circuits, especially in situations where electrical circuits need to be protected and external factors need to be prevented from affecting them. It is often used for ceilings, walls, or floors inside buildings

2025/10/14 08:37

The cables inside the vertical cable tray can be fixed using various methods, and the following are some common practices:1. Binding tape fixing method: Thread the binding tape through the cable and fix it on the inner wall of the bridge. This method is simple and easy to implement, but not

2025/10/14 08:37

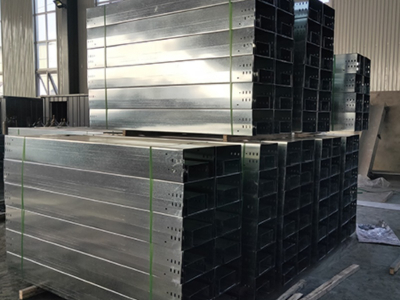

Steel cable tray is a metal structural system used to protect and support wires and cables. It is usually composed of steel plates and sections, and has the advantages of high structural strength, large bearing capacity, and good seismic performance.The following are some basic requirements for

2025/10/14 08:37

The production method of double-layer cable tray support is as follows:1. Material preparation: Two square tubes of appropriate length need to be prepared, and corresponding quantities of angle irons and screws need to be prepared according to the number of brackets to be processed. 2. Cutting

2025/09/30 16:06

Fiberglass cable tray is a type of cable tray made from glass fiber reinforced plastic (fiberglass). It boasts advantages such as corrosion resistance, anti-aging, lightweight yet high strength, and flexible design, making it widely used in power, communication, and industrial fields. The main

2025/09/30 16:06

The selection of bridge frames for power distribution rooms mainly depends on specific application scenarios and relevant specifications. The following are some common types of bridge frames for power distribution rooms and their applicable scenarios:1. Galvanized cable tray: Galvanized cable tray

2025/09/11 16:06

Grid cable trays are mainly used in the following scenarios:1. Indoor decoration and building wiring: Grid cable trays can be used in indoor and outdoor decoration projects, especially in places where flexible and adjustable wiring schemes are needed. For example, in large indoor spaces such as

2025/09/11 16:06