Galvanized Cable Tray

Galvanized cable trays have become an important component of cable routing systems due to their excellent performance and wide application.

Strong corrosion resistance: The galvanized layer effectively prevents steel from being corroded, prolongs the service life of the bridge, and is particularly suitable for environments with heavy moisture or corrosive gases.

High durability: With a sturdy structure and strong load-bearing capacity, it is suitable for supporting cables with large spans and heavy loads.

Easy installation and maintenance: Standardized design, easy and flexible installation, and convenient daily maintenance.

Good safety: The galvanized layer not only prevents rust, but also has certain fire resistance, reducing the risk of fire.

High cost-effectiveness: Compared to stainless steel cable trays, the material cost is lower, the anti-corrosion effect is excellent, and the cost-effectiveness is high.

Introduction of the product:

The maintenance techniques for galvanized cable trays mainly include the following points:

Regular inspection: Check the surface of the bridge, especially the welding points and connections, for corrosion or damage, and repair them in a timely manner.

Ensure that fasteners are securely fastened to prevent looseness from causing structural instability.

Cleaning and maintenance: Regularly clean the surface of the bridge, use warm water and neutral detergent, and avoid using acidic and alkaline cleaning agents.

After cleaning, wipe dry promptly and keep it dry.

Anti corrosion treatment: For areas where the galvanized layer is damaged, timely touch up coating should be carried out.

Regularly apply anti rust coating in damp or corrosive environments.

Load management: Follow the designed load and avoid overloading.

Maintain a reasonable layout of cables and reduce pressure.

Protective measures: Avoid direct contact of chemicals with the surface of the bridge.

Set up obstructions under extreme weather conditions.

Record feedback: Establish and maintain records for easy tracking and management in the future.

Promptly report any issues to professionals.

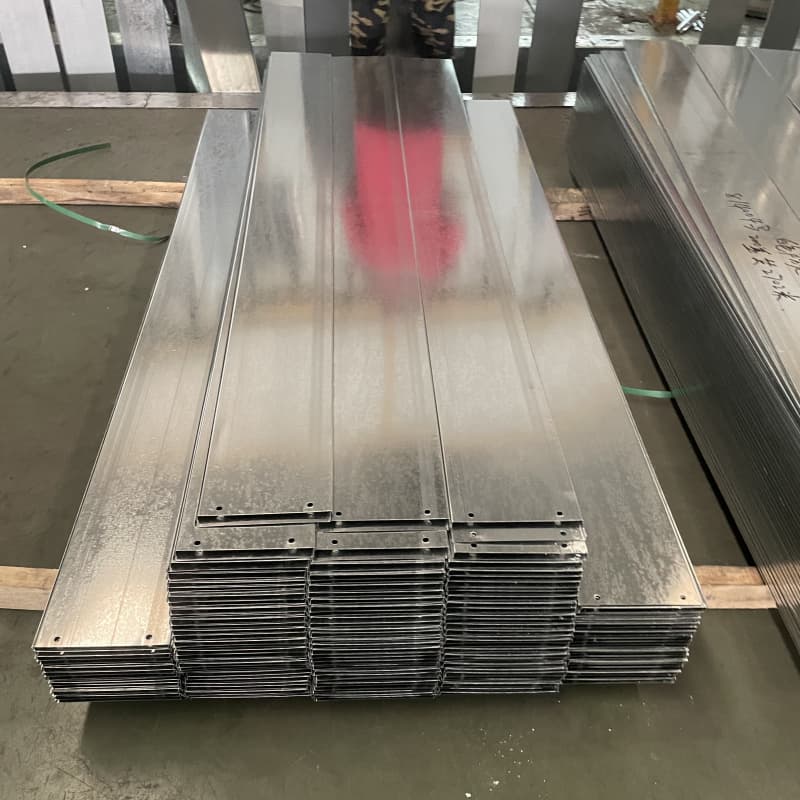

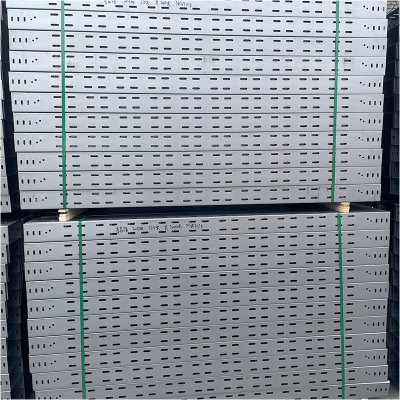

Production process:

Application:

Galvanized cable trays are widely used in industrial plants, commercial buildings, outdoor cable wiring, humid or highly corrosive environments, and special places with high requirements, such as chemical plants, petroleum refineries, power substations, communication base stations, subway systems, etc. In addition, it is also suitable for fields such as metallurgy, mining, agricultural facilities, as well as campus and public facilities, providing reliable protection and support for cables.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a high-quality service material supplier dedicated to the cable tray engineering industry for a long time. It adopts internationally advanced cable tray manufacturing technology and has a domestically leading cable tray one-time molding production line.

Our main products include galvanized cable trays, stainless steel cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our factory has strong technical strength, with professional product designers and management personnel. In the design and manufacturing of cable trays, we have also absorbed well-known technologies and experiences at home and abroad, and have guidance from experienced experts who have participated in cable tray design and manufacturing for many years. The components of the cable tray have been serialized and standardized. The novel form, reasonable structure, complete specifications, and flexible configuration have created powerful conditions for shortening the construction period of the project.

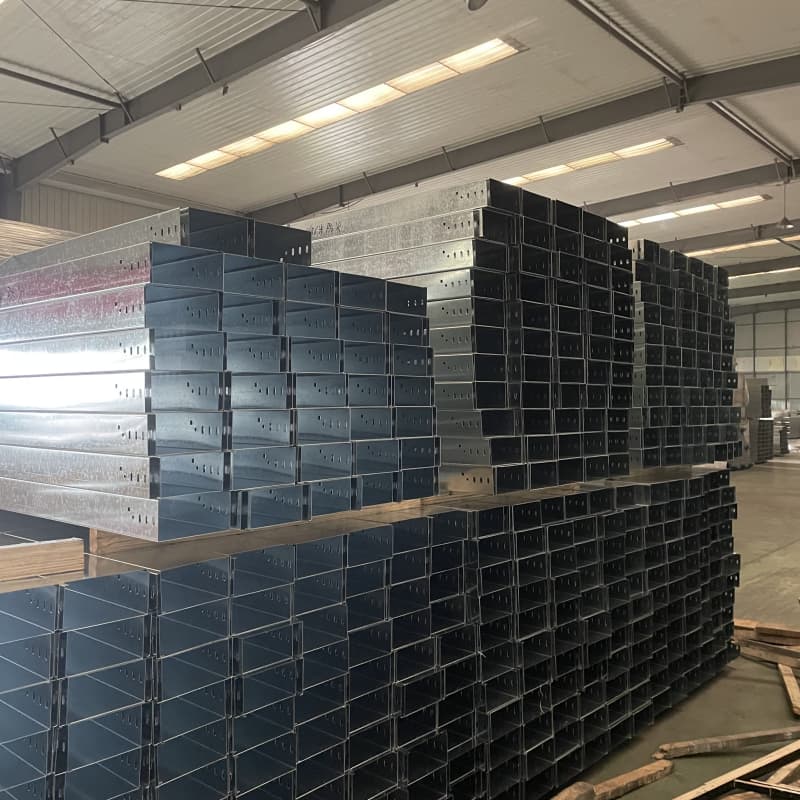

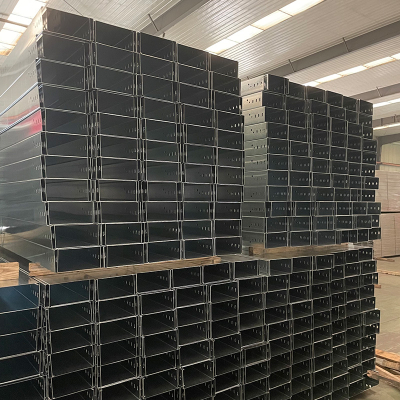

Production workshop: