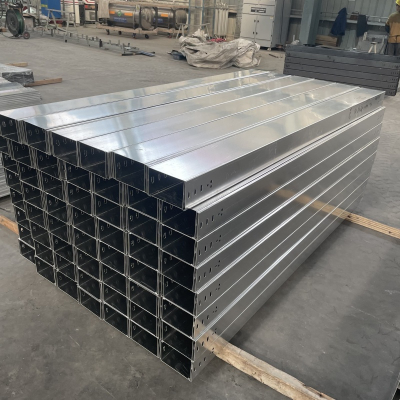

Construction precautions for galvanized cable trays

Galvanized cable trays can be divided into four models: stepped, tray, trough, and combination. The products include fire-resistant trays, stainless steel trays, fiberglass trays, aluminum alloy trays, etc. Galvanized cable trays are made of cold-rolled or hot-rolled steel plates, and surface treatments include painting, electroplating, hot-dip galvanizing, electrostatic spraying, etc. They are widely used in chemical, textile, power, machinery, automotive, electronics, national defense, building construction and other occasions. The company's galvanized cable trays can meet the requirements of different users and occasions, and can also be ordered and processed according to requirements. Galvanized connecting plates can be used as jumper wires between galvanized cable trays to connect them together. Galvanized spring washers can be added to the two connecting bolts at both ends of the connecting plates. Bridge frames that are painted, sprayed with plastic, or coated with other insulating materials should be bridged with soft copper wires. When the bridge passes through the deformation joints and straight sections of the building for more than 30 meters, compensation devices should be installed. Soft copper wires should be used to cross the discontinuous ends of the bridge, and expansion allowance should be left. Galvanized cable trays that can usually be used for large spans have their own performance characteristics. It refers to the ability to keep galvanized cable trays from oxidation and corrosion in a humid and hot state. Corrosion resistance refers to the ability of galvanized cable trays to withstand immersion in sulfuric acid, nitric acid, and acetic acid. Impact resistance refers to the restorative properties possessed by galvanized cable trays. Mainly, after being impacted, galvanized cable trays can still restore their original appearance.

The above is the basic performance that enables large-span galvanized cable trays.