What type of cable tray is used in the distribution room?

The selection of bridge frames for power distribution rooms mainly depends on specific application scenarios and relevant specifications. The following are some common types of bridge frames for power distribution rooms and their applicable scenarios:

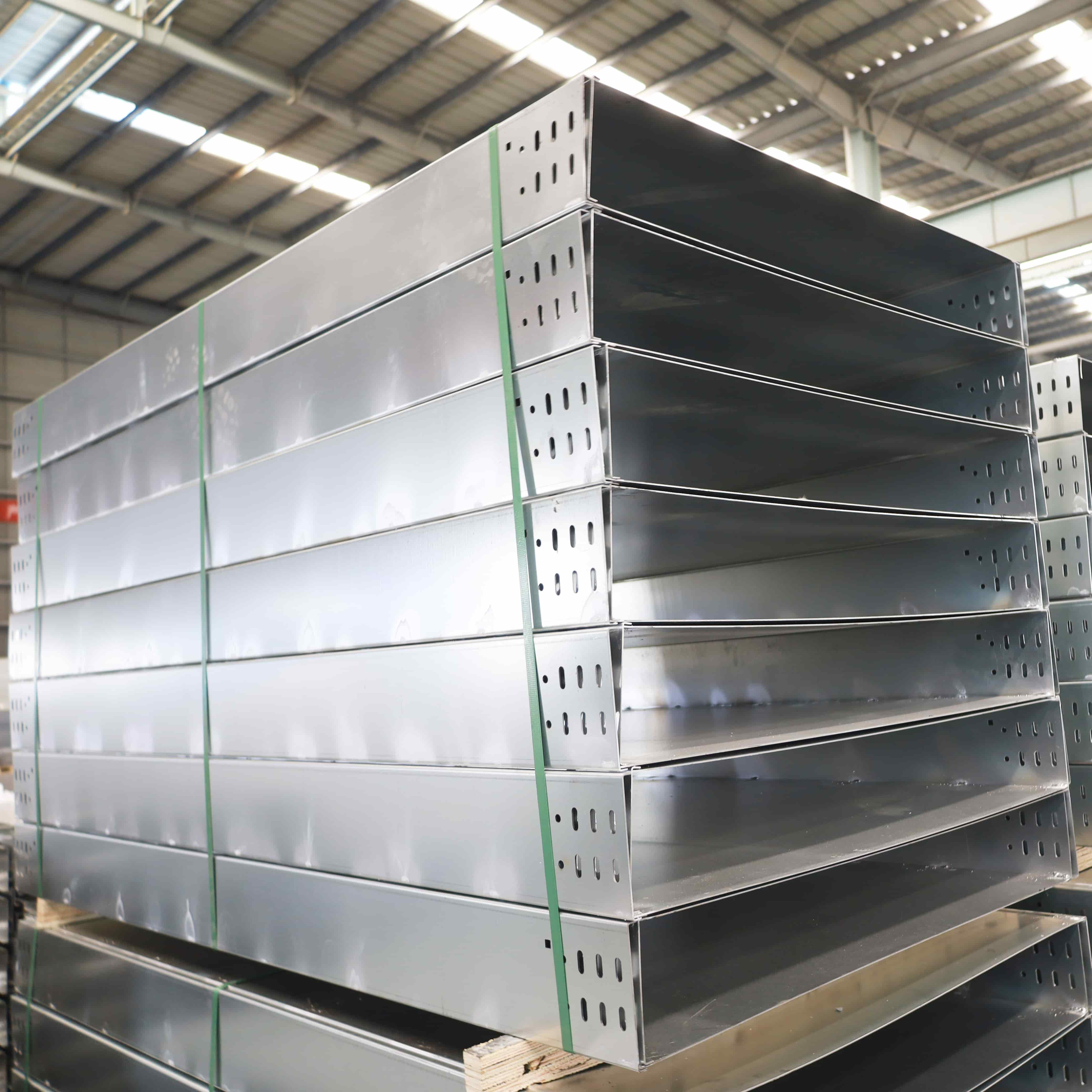

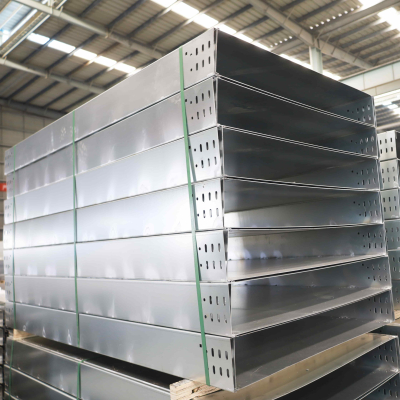

1. Galvanized cable tray: Galvanized cable tray is a type of cable tray with a layer of zinc coating on its surface, which has good anti-corrosion and conductivity properties, and is suitable for indoor and outdoor power distribution places.

2. Stainless steel bridge frame: Stainless steel bridge frame is a type of bridge frame made of stainless steel material, which has good corrosion resistance and aesthetics, and is suitable for high humidity and high pollution environments, such as the pharmaceutical, food and other industries.

3. Aluminum alloy cable tray: Aluminum alloy cable tray is a type of cable tray made of aluminum alloy material, which has a relatively light weight, good conductivity and anti-corrosion performance, and is suitable for indoor and outdoor power distribution places.

4. PVC cable tray: PVC cable tray is a type of cable tray made of polyvinyl chloride material, which has the characteristics of light weight, good anti-corrosion performance, and easy installation, and is suitable for indoor power distribution places.

5. Fiberglass cable tray: Fiberglass cable tray is a type of cable tray made of glass fiber reinforced plastic, which has the characteristics of light weight, good anti-corrosion performance, and easy processing. It is suitable for indoor and outdoor power distribution places.

When selecting the cable tray for the distribution room, the following factors should also be considered:

1. Whether the material meets the requirements: The material of the bridge must comply with relevant specifications to ensure its conductivity and anti-corrosion performance.

2. Whether the load capacity is sufficient: The load capacity of the bridge must be able to withstand the weight of the equipment and cables in the distribution room to ensure its stability and safety.

3. Whether the installation is convenient: When choosing a cable tray, it is necessary to consider whether its installation is convenient, simple, and easy for the staff to install and maintain.

4. Operating environment: The environment and temperature and humidity parameters inside the distribution room should also be taken into account in order to select suitable bridge materials and anti-corrosion coatings.

Taking into account the above factors, selecting the appropriate type of distribution room cable tray based on the specific situation is necessary to better meet the demand.