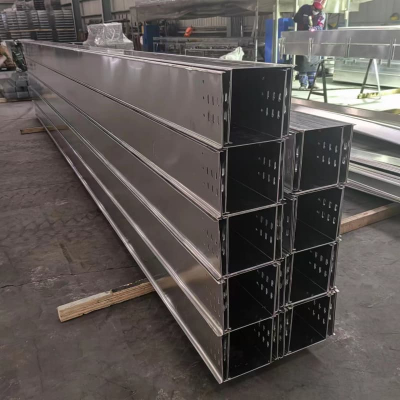

Polymer Alloy Cable Tray Manufacturer

The polymer cable tray is made of polymer composite material, supplying excessive mechanical power and

terrific corrosion resistance, making it appropriate for a range of complicated environments. It additionally gives terrific electrical insulation overall performance and climate resistance, making it perfect for high-voltage energy structures and out of doors cable wiring.

Introduction of the product:

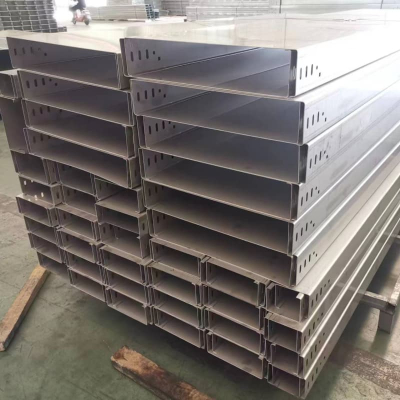

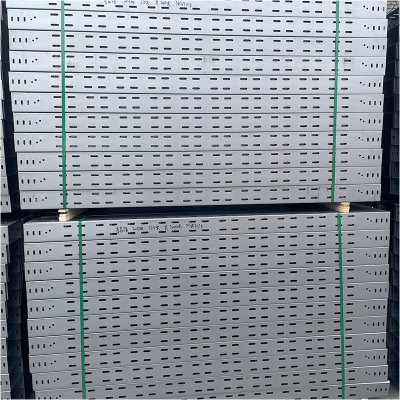

We presents polymer cable trays in a range of specs and lengths, made from state-of-the-art substances with precision manufacturing. The product presents most appropriate performance, which include corrosion resistance, durability, furnace resistance, and light-weight excessive strength. The cable tray lengths vary from 2000 mm to 6000 mm. It can additionally be personalized in accordance to customer-provided drawings to meet on-site set up necessities and enhance the normal integration and reliability of the system.

Production process:

Application:

Polymer cable trays have top corrosion resistance and can withstand the erosion of chemicals, so they are broadly used in environments such as chemical factories and petrochemical plants. Especially appropriate for cable laying in corrosive gases, acidic and alkaline environments. Polymer cable trays are no longer without difficulty corroded by way of salt spray, consequently they function properly in fields such as offshore platforms, offshore oil extraction, and transportation. It can adapt to harsh marine environments and make sure the protected association of cables.

Company Profile:

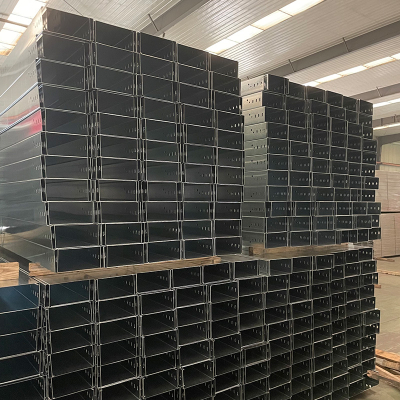

Shandong Bolt Electrical Equipment Co., Ltd. adopts internationally most surroundings high-quality cable tray manufacturing science and has a domestically predominant cable tray one-time molding manufacturing line.

Our quintessential merchandise consist of galvanized cable trays, stainless metal cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our manufacturing unit has sturdy technical strength, with professional product designers and administration personnel. In the shape and manufacturing of cable trays, we have in addition absorbed every and each and every day utilized sciences and experiences at domestic and abroad, and have instructing from expert authorities who have participated in cable tray shape and manufacturing for many years. The factors of the cable tray have been serialized and standardized. The novel form, best structure, total specifications, and bendy configuration have created pinnacle notch stipulations for shortening the inserting up dimension of the project.

Production workshop: