How to make cable tray elbows?

The production of cable tray elbows requires the following steps:

1. Determine the angle and required radius size of the elbow, and choose the appropriate elbow type based on these parameters, such as 90 degree elbow, 45 degree elbow, etc.

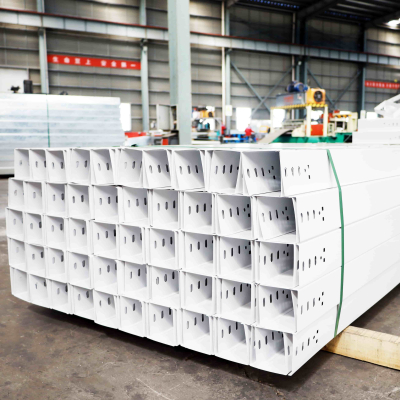

2. Choose suitable metal materials based on the specifications of the cable tray and the required size of the bends. Common materials include galvanized sheet, stainless steel sheet, etc.

3. Cut and bend metal materials according to size and angle requirements. Generally speaking, a shearing machine can be used for cutting, and a bending machine can be used for bending processing.

For some larger cable tray bends, assembly and welding are required. This step requires the use of professional equipment such as welding machines, while also paying attention to welding quality and safety issues.

5. Finally, perform surface treatment and inspection on the completed cable tray bends. Surface treatment can be achieved through methods such as painting, and inspection mainly involves the accuracy of dimensions and angles, as well as strength and other indicators.

Making cable tray elbows requires certain professional knowledge and skills, as well as attention to safety and environmental protection issues. During the production process, relevant industry standards and specifications should be followed to ensure product quality and personnel safety.