Which of the three types of cable trays, namely trough type cable tray, tray type cable tray, and step type cable tray, has the best heat dissipation?

The heat dissipation performance of trough bridge, tray bridge, and stepped bridge depends on their design and materials. Generally speaking, the heat dissipation performance of cable trays can be evaluated by the following factors:

1. Thermal conductivity of bridge material: The better the thermal conductivity of the material, the more effectively it can transfer heat. Common bridge materials include aluminum alloy, stainless steel, galvanized sheet, etc. Among them, aluminum alloy and stainless steel have better thermal conductivity.

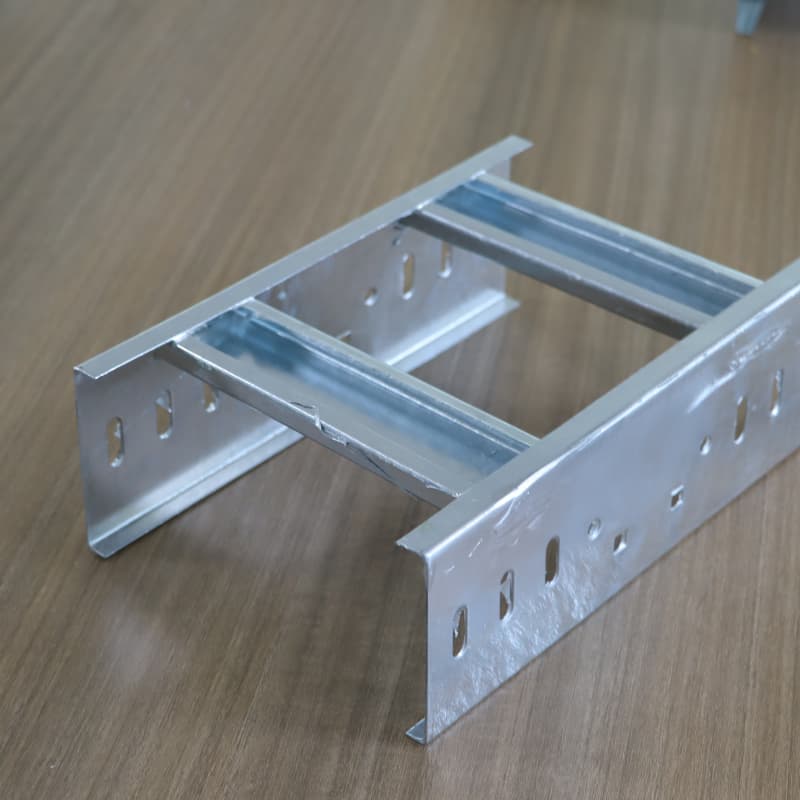

2. Bridge design: Different bridge designs can affect their heat dissipation effect. For example, the groove cover design of the trough type cable tray can increase the heat dissipation area, the tray design of the trough type cable tray can better disperse the heat of the cable, and the stepped design of the stepped type cable tray can increase the air flow on the surface of the cable tray.

3. Usage environment: The usage environment and temperature of the bridge frame can also affect its heat dissipation effect. If the bridge is used in a high-temperature environment, the heat dissipation performance is even more important.

Therefore, for the three types of cable trays, which one has the best heat dissipation cannot be simply answered. Different cable trays have different heat dissipation performance in different usage environments. When choosing a bridge frame, it is necessary to consider the above factors and choose the type of bridge frame that is suitable for oneself. If better heat dissipation is needed, you can consider increasing the heat dissipation area of the bridge or adding heat dissipation equipment.