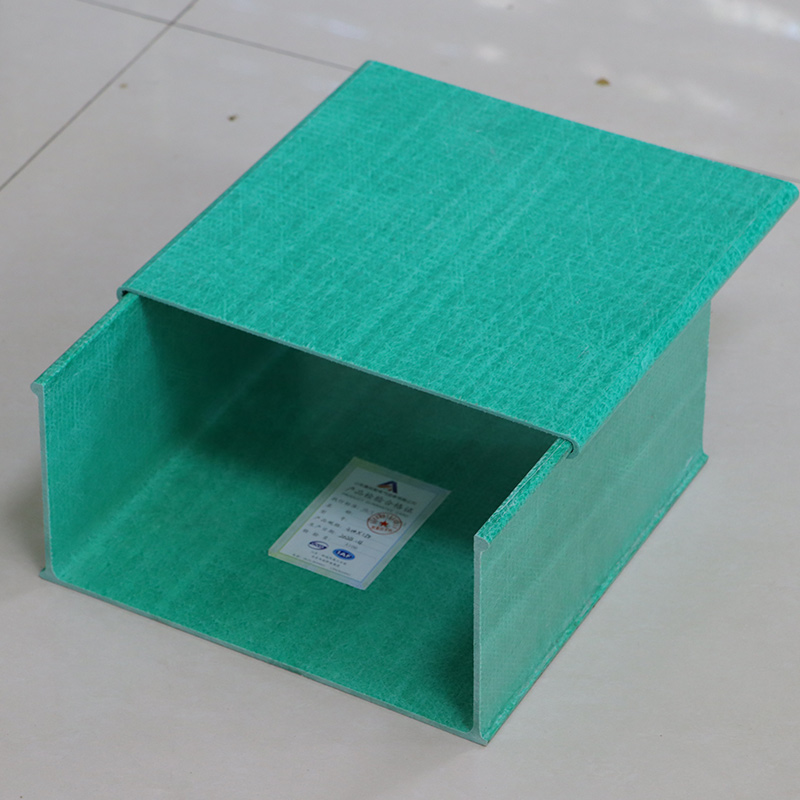

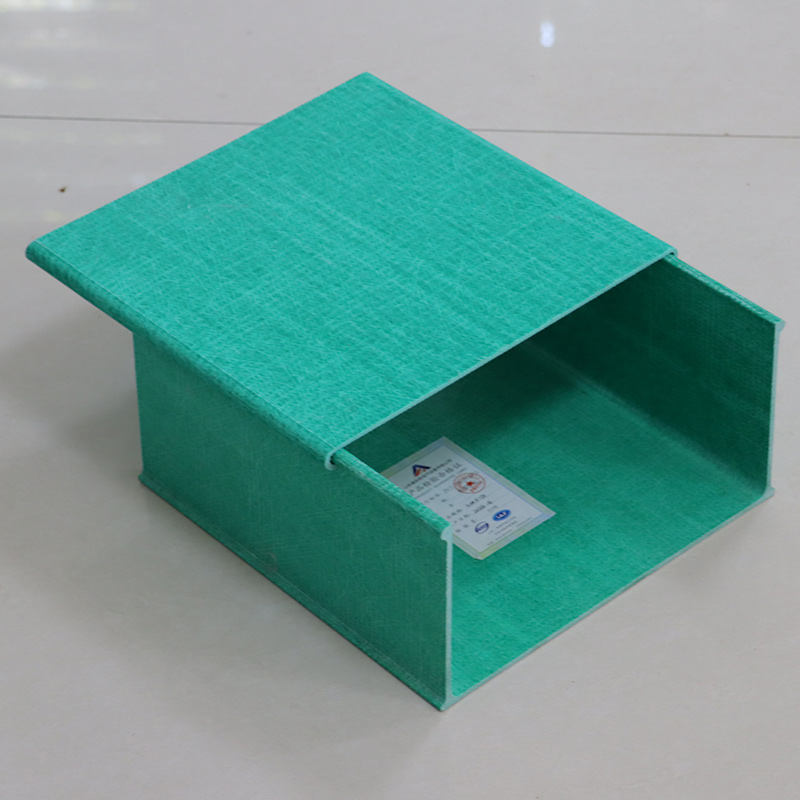

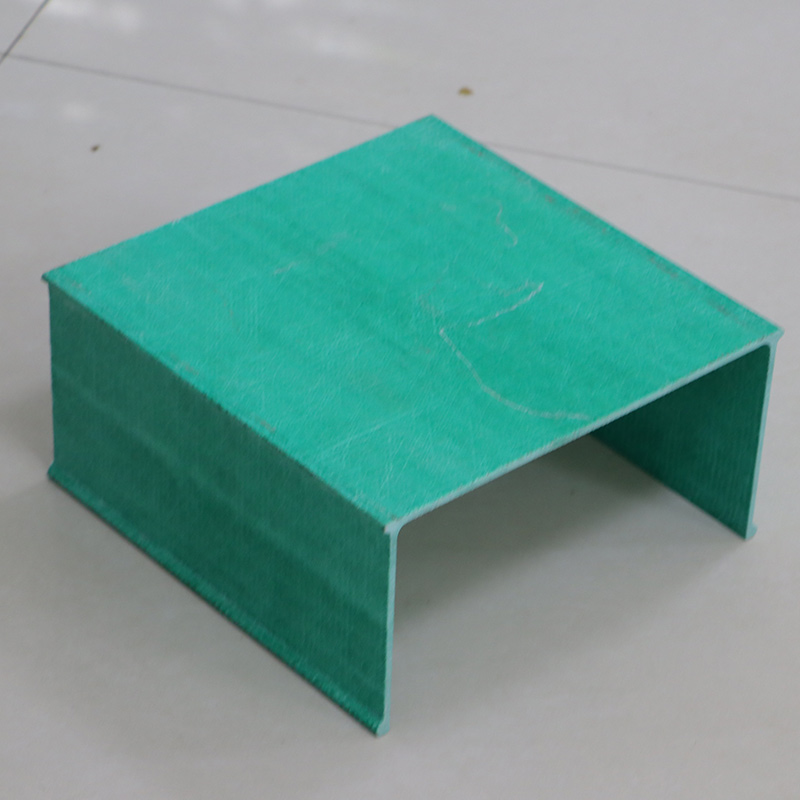

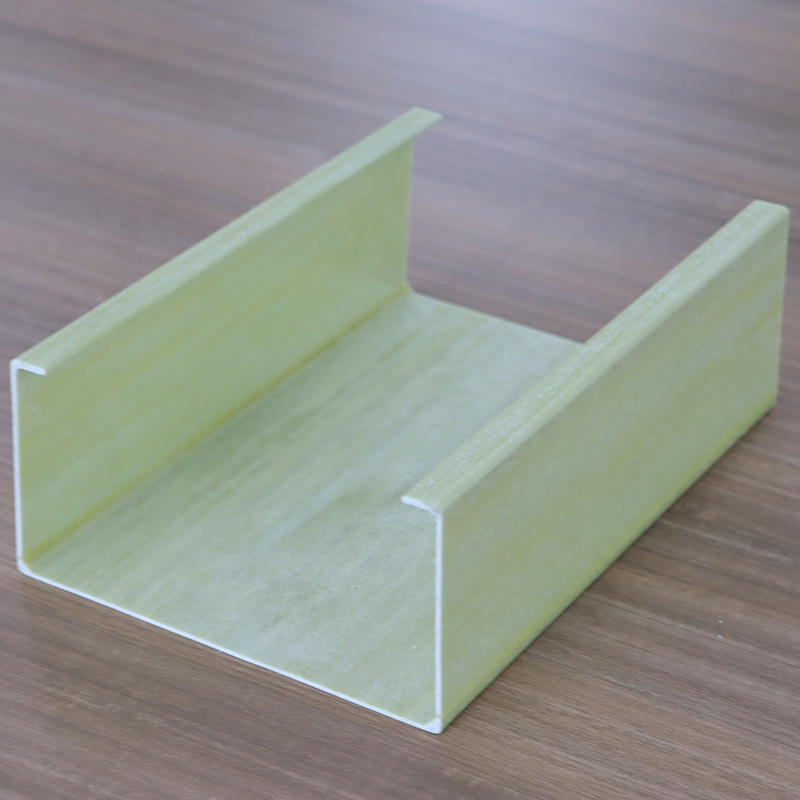

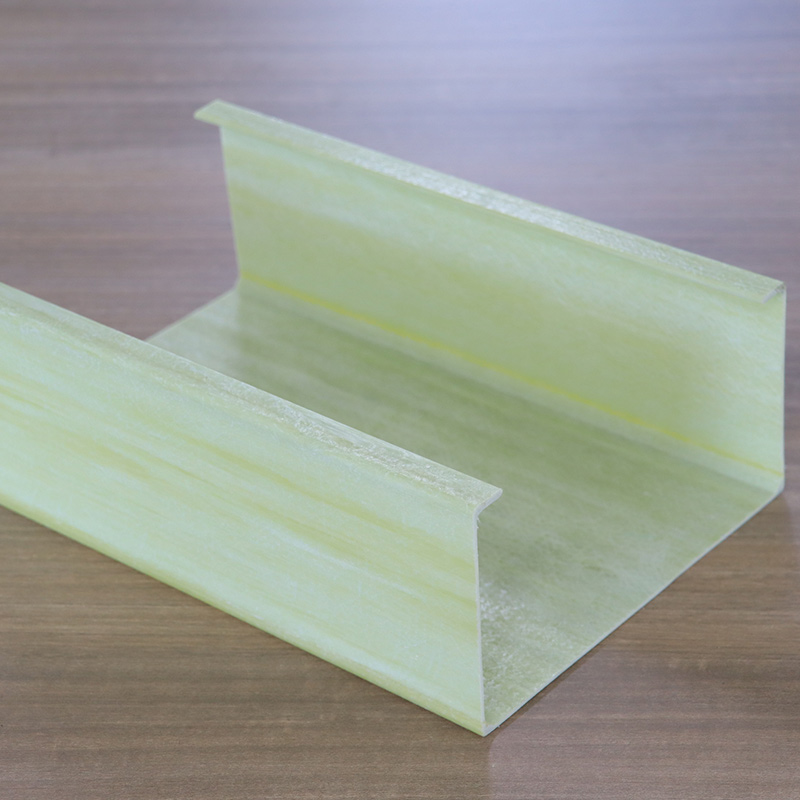

Fiberglass Composite Epoxy Resin Cable Tray

1. Corrosion Resistant: Withstands acids, alkalis, and chemicals, ideal for tough environments.

2. Light & Strong: Easy to transport and install, reducing workload.

3. Good Insulation: Prevents leakage and interference.

4. High Temp Resistant: Endures high heat, suitable for hot conditions.

5. Fire Resistant: Epoxy resin ensures safety in fires.

6. UV & Weather Resistant: Long-lasting for outdoor use.

7. Impact Resistant: Withstands mechanical damage.

8. Eco-friendly: Non-toxic, meets green standards.

9. Low Maintenance: Durable, reducing upkeep costs.

10. Aesthetic: Smooth, modern look for any environment.

When it comes to organizing and protecting electrical cables, a fiberglass composite epoxy resin cable tray stands out as an innovative and highly reliable option. Combining the strength of fiberglass with the superior chemical resistance of epoxy resin, this cable tray offers unmatched durability and longevity — ideal for harsh industrial environments where traditional metal trays might fail.

What Is a Fiberglass Composite Epoxy Resin Cable Tray?

A fiberglass composite epoxy resin cable tray is a specialized cable management system constructed from fiberglass reinforced with epoxy resin matrix. This composite material results in a lightweight yet incredibly strong tray, resistant to corrosion, chemicals, moisture, and extreme temperatures.

These trays provide a safe, organized pathway for electrical wiring in facilities such as power plants, offshore platforms, chemical plants, and manufacturing factories.

Why Choose Fiberglass Composite Epoxy Resin Cable Trays?

1. Exceptional Corrosion Resistance

Unlike steel or aluminum trays, fiberglass composite epoxy resin cable trays resist rust and corrosion, making them perfect for outdoor, marine, and chemical-exposed environments.

2. High Strength-to-Weight Ratio

The fiberglass composite structure delivers excellent mechanical strength while remaining lighter than metal alternatives, simplifying installation and reducing structural load.

3. Chemical and UV Resistance

Epoxy resin offers strong resistance against acids, alkalis, solvents, and UV rays, ensuring the tray’s integrity even in the most aggressive conditions.

4. Electrical Insulation

The non-conductive nature of fiberglass epoxy composite enhances electrical safety, reducing risks of short circuits or ground faults.

5. Low Maintenance

Fiberglass composite trays require minimal upkeep, saving costs on repainting, repairs, or replacements over time.

Common Applications of Fiberglass Composite Epoxy Resin Cable Trays

Industrial plants with corrosive atmospheres

Offshore oil rigs and marine vessels

Wastewater treatment facilities

Power generation stations

Chemical processing plants

Key Features to Look for in Fiberglass Composite Epoxy Resin Cable Trays

Load Capacity: Ensure the tray supports the weight of your cables and any additional equipment.

Size and Configuration: Choose from ladder, perforated, or solid-bottom designs depending on ventilation and cable type.

Fire Resistance: Some trays offer enhanced fire retardant properties — essential for safety compliance.

Custom Fabrication: Many manufacturers provide custom lengths, bends, and fittings tailored to your project.

Installation Tips for Fiberglass Composite Epoxy Resin Cable Trays

Use compatible fasteners and supports to avoid galvanic corrosion.

Follow manufacturer guidelines for maximum span and load limits.

Inspect trays periodically for physical damage or wear.

Consider professional installation for complex layouts.

Real User Feedback

⭐⭐⭐⭐⭐

“Switching to fiberglass composite epoxy resin cable trays drastically improved our facility’s corrosion resistance. Installation was easier due to the lightweight material.”

— Kevin L., Plant Maintenance Supervisor

⭐⭐⭐⭐

“The electrical insulation properties give us peace of mind in a high-voltage environment. These trays outperform metal trays in harsh chemical zones.”

— Sandra M., Electrical Engineer

⭐⭐⭐⭐⭐

“Custom sizes and configurations allowed us to perfectly fit the trays into our complex wiring system. Highly recommend for industrial use.”

— David R., Project Manager

Why Our Fiberglass Composite Epoxy Resin Cable Trays Stand Out

We deliver high-quality fiberglass composite epoxy resin cable trays that meet stringent industry standards. Our products feature:

Premium-grade raw materials for lasting performance

Precision manufacturing ensuring dimensional accuracy

Comprehensive after-sales support and technical advice

Competitive pricing with customizable options

Conclusion: The Smart Choice for Long-Lasting Cable Management

Choosing a fiberglass composite epoxy resin cable tray means investing in a durable, corrosion-proof, and lightweight solution designed for demanding industrial applications. Enhance your electrical infrastructure with trays that combine strength, safety, and sustainability.

Ready to upgrade your cable management system? Contact us today for a free consultation and quote.

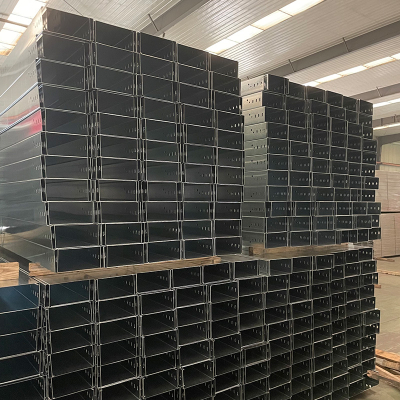

Production process:

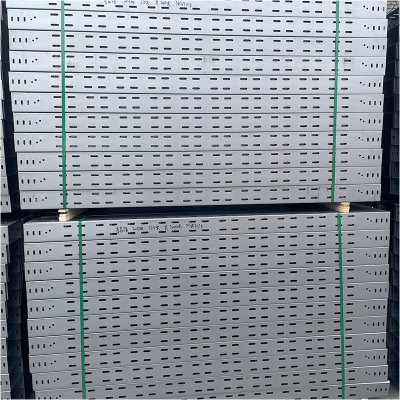

Application:

Cable trays are commonly used in a variety of applications, particularly in buildings, facilities, or equipment that require extensive cable installations. Their primary function is to support and protect cables, ensuring safe operation and efficient cable management.

In the production facilities of electric power, chemical industry, metallurgy and other industries, cable tray is used to manage and protect power transmission, signaling and control cables.

In power plants, steel mills, oil refineries and other places, cable tray can ensure the safe laying of cable systems and avoid cables being affected by external factors, such as fire and mechanical damage.