Vertical Shaft Metal Cable Tray

Vertical shaft cable trays play an vital function in electrical systems, and their sketch and determination want to think about a couple of factors.

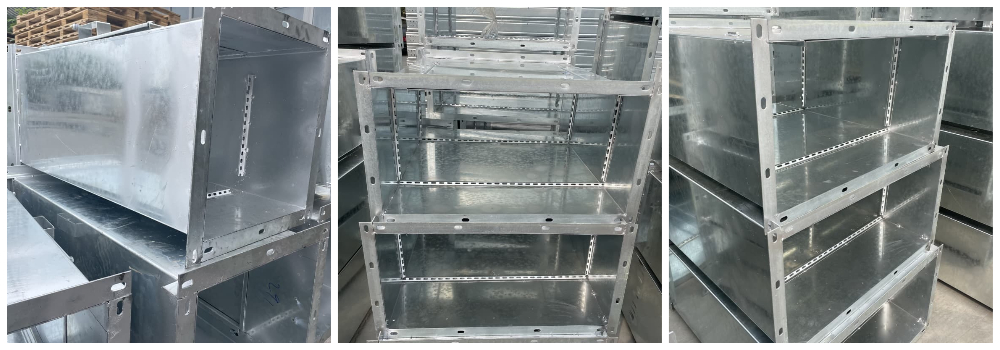

The vertical shaft cable tray adopts light-weight design, extensively decreasing development costs, minimizing vertical shaft loads, and possessing amazing thermal conductivity, which can efficiently enhance warmness dissipation

effectivity and lengthen cable life. In addition, it additionally adopts low-energy manufacturing technology, meets inexperienced constructing standards, and has excessive corrosion resistance and strength, extending carrier existence and decreasing preservation costs.

Introduction of the product:

When deciding on a vertical shaft cable tray, it is crucial to think about the on-site surroundings and technical requirements. If it is essential to defend electrical interference or shield in opposition to exterior environmental influences, a precise kind of cable tray must be selected. During the set up process, sure technological techniques have to be followed, which includes positioning and laying out, embedding iron components or growth bolts, etc., to make sure the steadiness and security of the bridge.

Vertical shaft cable trays play an essential position in electrical systems. Their light-weight design, terrific thermal conductivity, and low-energy manufacturing procedure make them appreciably fine in enhancing development efficiency, decreasing electricity consumption, and extending carrier life. When deciding on and installing, it is integral to think about the unique state of affairs to make certain its steadiness and safety.

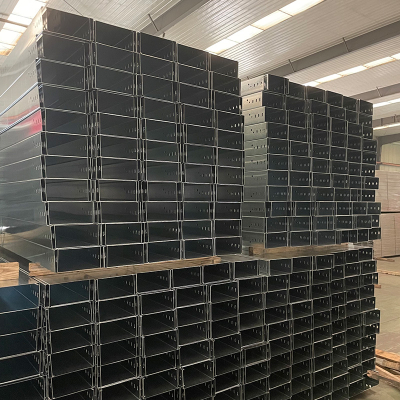

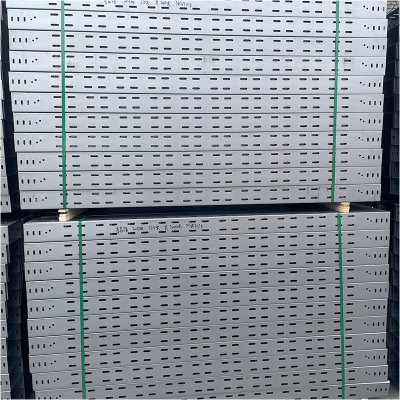

Production process:

Shipping Process:

We are a producer specializing in the manufacturing of cable trays for many years. We have a professional form team, manufacturing team, and brilliant inspection crew to make fantastic that every purchaser can customize merchandise that meet their needs.

The agency has a whole fluctuate of products, which embody stainless metallic cable trays, galvanized cable trays, aluminum alloy cable trays, trapezoidal cable trays, perforated cable trays, steel wire mesh cable trays, etc. The flooring treatment methods for bridges consist of fire-resistant bridge trays, hot-dip galvanized bridge trays, hot-dip galvanized bridge trays, painted bridge trays, coloration steel bridge trays, etc.

Application:

The primary substances for vertical shaft cable trays consist of the following:

Steel bridge frame:

Cold rolled metal plate: High cost-effectiveness, appropriate for accepted indoor environments, requiring floor cure for corrosion prevention.

Hot dip galvanized metal plate: Strong corrosion resistance, appropriate for out of doors or high humidity environments.

Stainless steel: Excellent corrosion resistance, appropriate for fairly corrosive environments such as chemical plants, beaches, etc.

Aluminum alloy bridge: lightweight, corrosion-resistant, appropriate for indoor and conventional out of doors environments, with precise warmth dissipation and ornamental properties, handy to install.

Fiberglass bridge frame: made of glass fiber strengthened plastic, with exceptional corrosion resistance and furnace resistance, appropriate for robust corrosive environments, and properly insulation performance.

Spray painted bridge: The floor is dealt with with spray coating to amplify corrosion resistance and climate resistance, and is typically used in indoor or normal outside environments.

Composite cloth bridge: such as polyurethane composite material, which is corrosion-resistant, growing older resistant, and has excellent insulation properties, appropriate for environments with sturdy electromagnetic interference or excessive corrosiveness.

When deciding on materials, it is crucial to comprehensively think about elements such as utilization environment, load requirements, corrosion resistance, and budget.

Company Profile:

Shandong Bolte Electrical Equipment Co., Ltd. is a remarkable corporation cloth commercial enterprise company dedicated to the cable tray engineering industry. Located in Liaocheng, Shandong Province, the organization specializes in the research, development, production, sales, and set up of cable trays. Utilizing internationally most appropriate cable tray manufacturing processes, it boasts a domestically quintessential one-time molding manufacturing line for cable trays. Currently, the manufacturing unit spans 20,000 rectangular meters, employs over 230 staff, and achieves an usual day by using day output of about a hundred and twenty tons. It possesses extra than one built-in manufacturing traces and in particular a few computerized equipment. The commercial enterprise company agency mostly affords large than a few elements and patterns of cable trays, which consists of galvanized trays, stainless metal trays, aluminum alloy trays, fireproof trays, and polymer trays. Adhering to the corporation philosophy of "quality as the foundation, integrity as the guarantee, excessive nice management, and revolutionary development," and the organization organization motive of "customer-centric," the manufacturing unit constantly strives for perfection, actually affords as soon as extra to society, and needs to create a incredible future for clear waters and blue skies with pretty acceptable merchandise and nice services.

Production workshop: