How to install cable metal bridge trays?

A cable metal tray is a facility used to support and protect cables, typically composed of steel plates or profiles. Here are some basic requirements for making cable metal trays:

1. Material selection: The material for cable metal trays should be selected according to the usage environment and cable type. Common materials include carbon steel, stainless steel, aluminum alloy, etc.

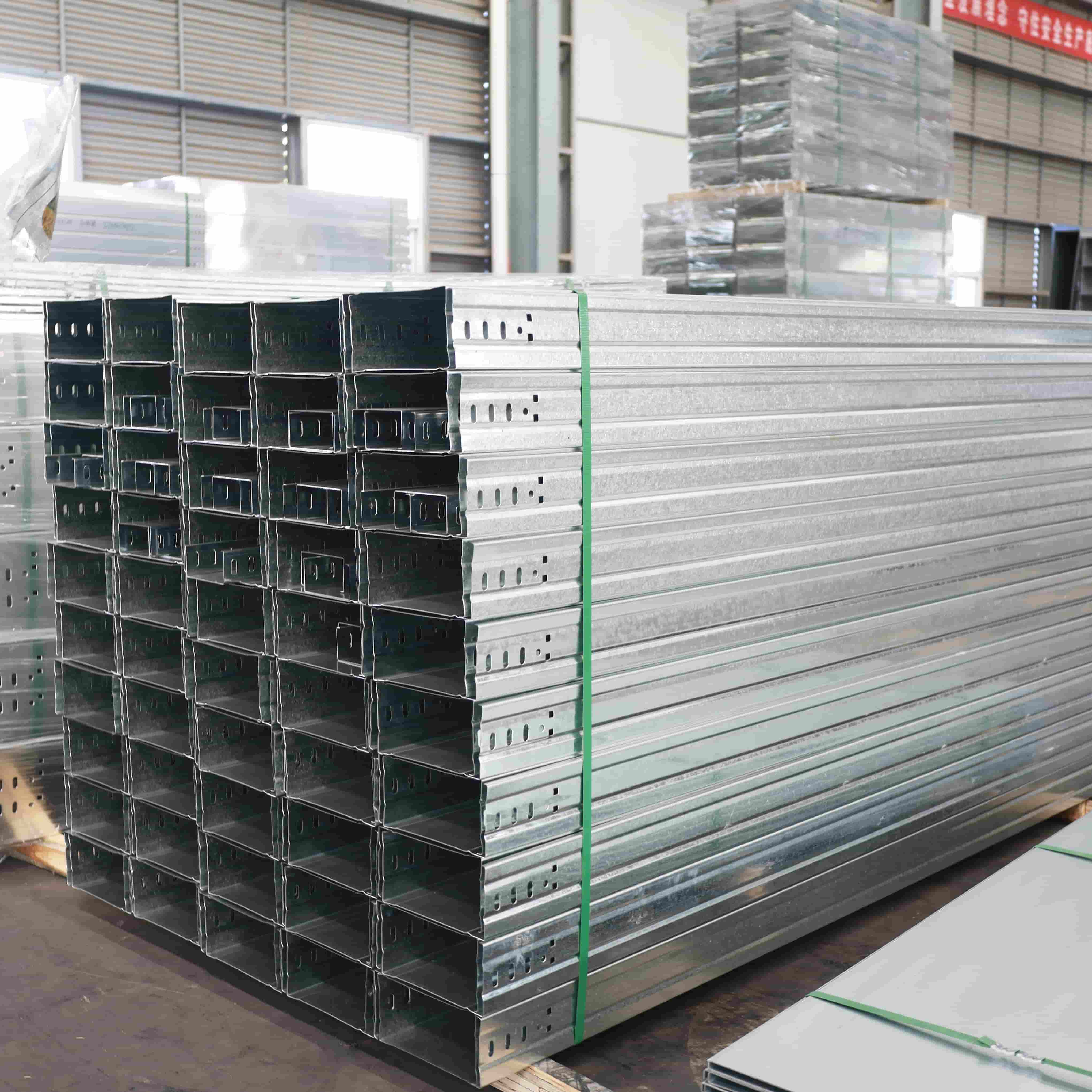

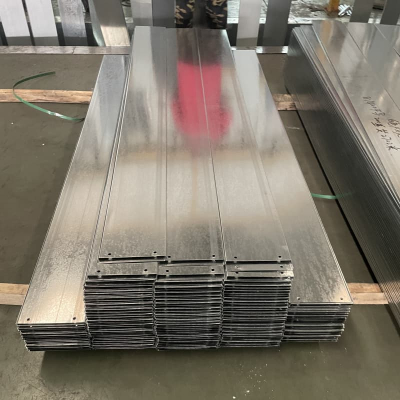

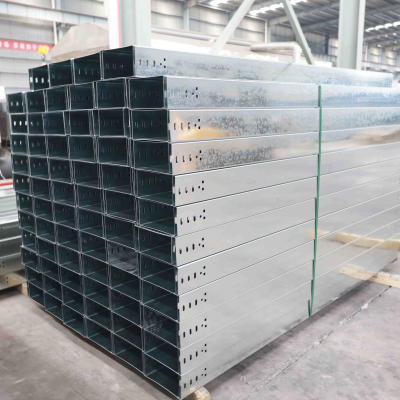

2. Structural design: The structural design of cable metal trays should consider factors such as strength, stability, and ease of installation. Usually, different forms such as trapezoidal, tray shaped, and groove shaped are used, and the selection is based on the specific usage scenario.

3. Surface treatment: The surface treatment of cable metal trays should be selected according to the usage environment. Common surface treatment methods include galvanizing, spraying, baking paint, etc., to improve the corrosion resistance of the bridge.

4. Size specifications: The size specifications of cable metal trays should be selected according to the usage scenario and the number of cables. Usually, the width and height of the cable tray should be designed according to the outer diameter and bending radius of the cable to ensure that the cable can pass smoothly through the tray.

5. Connection method: The connection method of cable metal trays should consider installation convenience and firmness. Usually, different methods such as welding, bolt connection, and plugging are used, and the selection is based on the specific scenario.

In short, the production of cable metal trays requires consideration of factors such as materials, structure, surface treatment, size specifications, and connection methods to ensure the strength, stability, and corrosion resistance of the trays, while meeting installation and usage requirements.