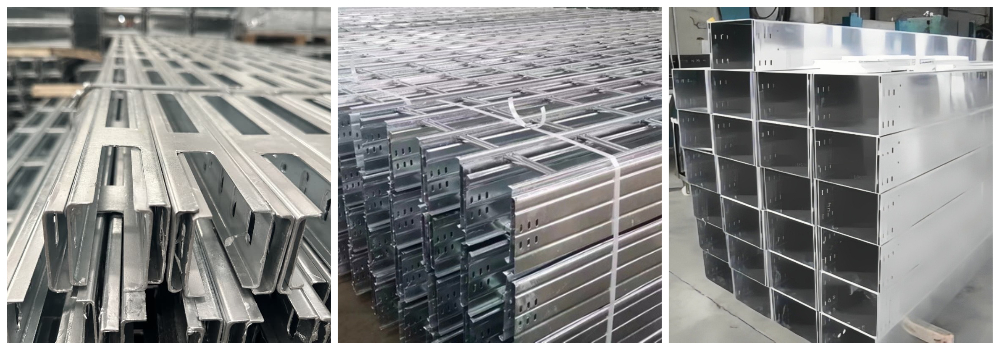

Hot Dip Galvanized Ladder Cable Tray

The utilization surroundings of hot-dip galvanized cable tray:

1. Outdoor and humid environments: Hot dip galvanized cable trays are in most instances appropriate for outdoor, humid, or superbly corrosive environments, such as coastal areas, chemical plants, etc. They can effectively face up to the erosion of chemical sources such as moisture and acidity in the air.

2. Industrial air air air pollution environment: In cautiously polluted environments with excessive smoke content, hot-dip galvanized cable trays can in addition preserve long-term anti-corrosion penalties and are first-rate for places such as chemical vegetation and sewage treatment plants.

Introduction of the product:

The most important points of hot-dip galvanized cable trays are mirrored in the following aspects:

1. Provide constant assist and protection: Provide consistent and reliable aid for cables to maintain away from mechanical damage prompted via ability of cable scattering.

2. Anti corrosion and extended company life: The bridge physique dealt with with hot-dip galvanizing has right corrosion resistance, which can stand up to the erosion of harsh environments such as moisture, acid and alkali, and extend the service existence of cables and bridge frames.

3. Ensure electrical safety: The hot-dip galvanized layer can serve as a protecting barrier, reducing electrical contact troubles added about by way of metal corrosion and making positive the blanketed operation of the electrical system.

4. Enhance mechanical performance: The galvanized layer now no longer fully offers anti-corrosion protection, alternatively moreover enhances the flooring hardness of the bridge, improving its ability to face up to friction and collision.

5. Meet organisation necessities and aesthetic requirements: In some specific industries and projects, hot-dip galvanizing has cease up a general requirement for cable trays, and its flooring is smooth, handy and beautiful, splendid for uncovered set up in public areas.

Production process:

Application:

Hot dip galvanized cable trays are greatly used in the constructing corporation to assist and wire electrical equipment, lighting fixtures fixtures equipment, etc. inner buildings, presenting connectivity for electrical energy and dialog facilities. In industrial manufacturing and manufacturing processes, they are used to assist and protect cable wiring for manufacturing unit equipment, mechanical equipment, etc., making certain the consistent operation of industrial equipment. It moreover performs an quintessential characteristic in fields such as picture voltaic and wind energy, such as cable traces used for placing in and protecting photovoltaic panels or wind turbines. In addition, hot-dip galvanized cable trays are in precise terrific for outdoor, humid, or in particular corrosive environments due to their remarkable corrosion resistance.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a tremendously real agency fabric company devoted to the cable tray engineering industrial employer company for a prolonged time. It adopts internationally most environment extremely good cable tray manufacturing science and has a domestically predominant cable tray one-time molding manufacturing line.

Our quintessential merchandise consist of galvanized cable trays, stainless steel cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our manufacturing unit has sturdy technical strength, with expert product designers and administration personnel. In the graph and manufacturing of cable trays, we have in addition absorbed everyday utilized sciences and experiences at domestic and abroad, and have instructing from professional authorities who have participated in cable tray form and manufacturing for many years. The elements of the cable tray have been serialized and standardized. The novel form, smart structure, whole specifications, and flexible configuration have created pinnacle notch stipulations for shortening the inserting up dimension of the project.

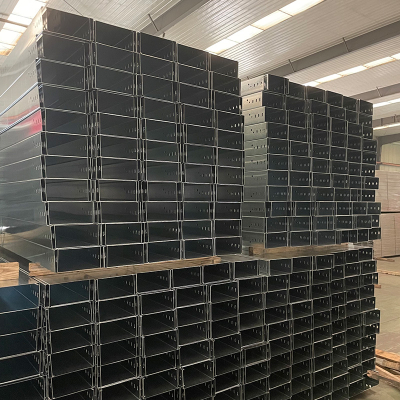

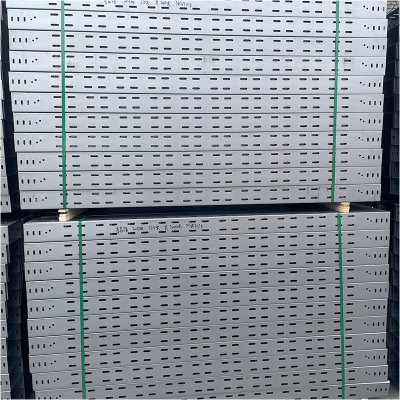

Production workshop: