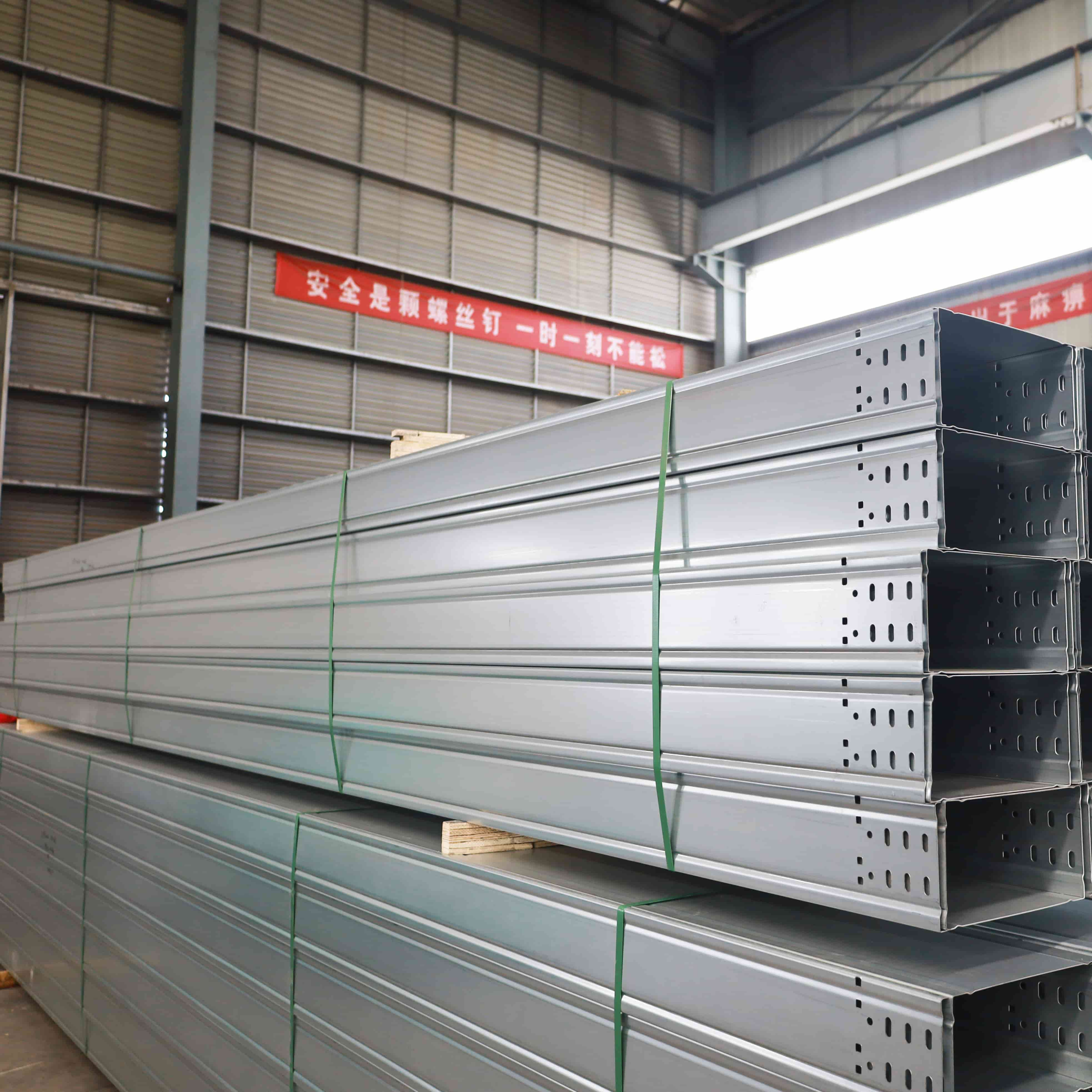

Large Span Ladder Cable Tray

Large span cable trays are widely utilized in many different industries, especially in places where the problem of cables that are too long and span too large needs to be resolved.

In order to improve wiring effectiveness and administration level, large span cable trays are frequently used in industries like power, communication, petrochemicals, transportation, and construction, as well as in large factories, shopping centers, hospitals, schools, and more.

Introduction of the product:

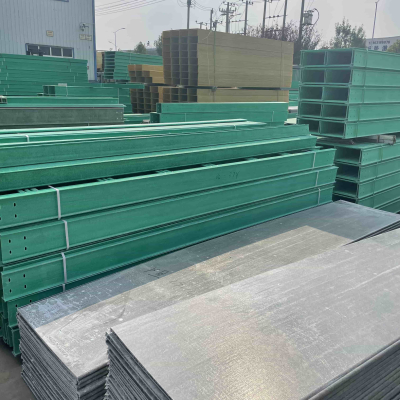

Large-span cable trays can be constructed from a variety of materials, including fiberglass, aluminum alloy, galvanized steel, and others, depending on the environment and specifications. Aluminum alloy cable trays are lightweight and easy to install and maintain, while the metal galvanized bridge is suitable for humid and corrosive conditions due to its strong corrosion resistance and exceptional durability.

To ensure the safe and secure operation of cables, the large-span cable tray graph wants to consider factors such cable fixation, tray width, and aid spacing.

In conclusion, because of their wide range of applications and multiple fabric options, large-span cable trays have become a crucial solution for cable routing issues.

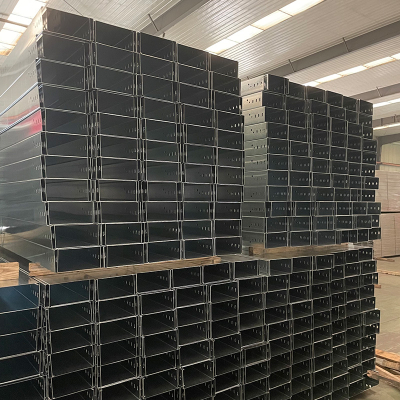

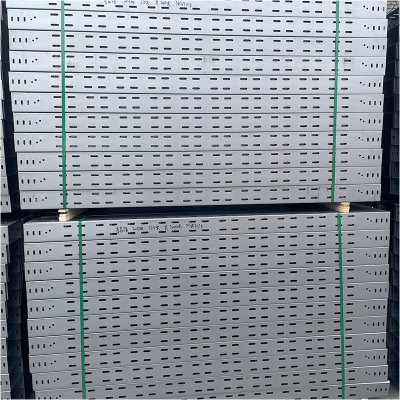

Production process:

Shipping Process:

For many years, we have been a manufacturer with a focus on producing cable trays. We have a skilled manufacturing team, a professional structure team, and an amazing inspection crew to ensure that every customer may personalize products to suit their needs.

The company offers a wide range of goods, including metal wire mesh cable trays, stainless steel cable trays, aluminum alloy cable trays, trapezoidal cable trays, perforated cable trays, and galvanized cable trays. Fire-resistant bridge trays, hot-dip galvanized bridge trays, painted bridge trays, colored metal bridge trays, and more bridge floor therapeutic approaches are available.

Application:

When choosing an appropriate large-span cable tray, the following elements should be taken into account:

Selection of materials:

Steel is strong and resistant to corrosion, but it is expensive and heavy.

Aluminum is a costly, lightweight, strong, and corrosion-resistant material.

Fiberglass reinforced plastic is expensive but lightweight, strong, and resistant to corrosion.

Design elements:

Span: Steel or fiberglass-reinforced plastic is advised for large spans, which call for greater strength and stability.

Load: To make sure the end can support heavy cantilever loads, the cable tray's bearing capacity must be taken into account.

Path: To adjust to various pathways and heights, select materials with excellent processing performance and high corrosion resistance.

Installation and maintenance:

Conduct on-site survey before installation, develop detailed plans, and ensure that the quality of the bridge meets the requirements.

During installation, follow the design requirements and pay attention to the filling rate, layout, and fixation of cables.

Company Profile:

An outstanding material industrial employer company dedicated to the cable tray engineering sector is Shandong Bolte Electrical Equipment Co., Ltd. The employer, which is based in Liaocheng, Shandong Province, is an expert in cable tray research, development, manufacturing, sales, and setup. It has a domestically iconic one-time molding cable tray manufacturing line that uses the most amazing cable tray manufacturing procedures in the world. The production facility currently occupies 20,000 square meters, has over 230 employees, and uses a daily output of over 120 tons to accomplish a favored day. It has multiple integrated manufacturing tracks and, in particular, some digital machinery. The company's employer often has access to a large number of different types of cable trays, including fireproof, polymer, aluminum alloy, stainless steel, and galvanized trays. Following the company's philosophy of "quality as the foundation, integrity as the guarantee, immoderate satisfactory management, and modern-day development," as well as the enterprise employer organization's motivation of "customer-centric," the manufacturing unit consistently aims for excellence, actually provides for society as soon as possible, and aspires to build a magnificent future for clear waters and blue skies with reasonably priced goods and excellent services.

Production workshop: