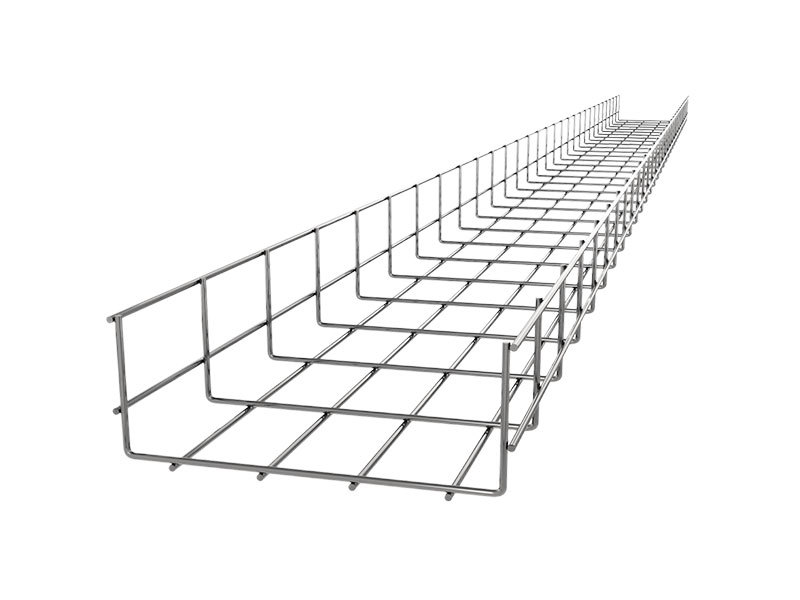

Mesh Cable Tray Customization

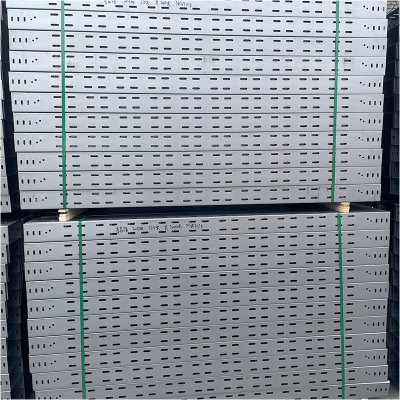

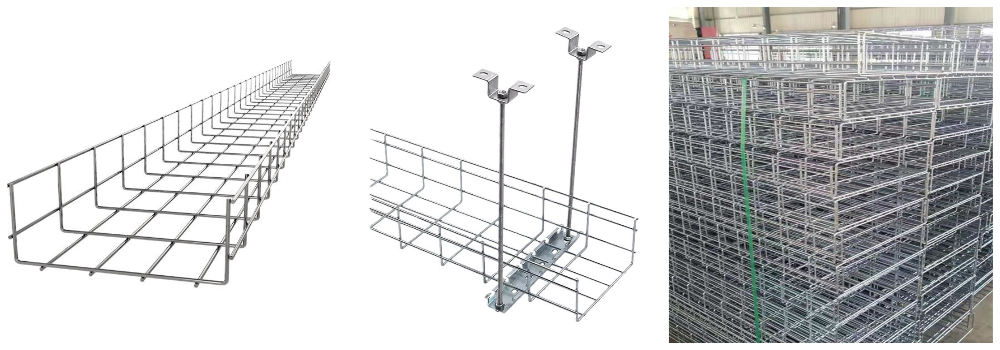

The raw material of the grid cable tray is steel wire, which is welded and formed, and finally subjected to surface treatment. Mainly used in computer rooms, usually every 3 meters,

Material: galvanized, hot-dip galvanized, stainless steel

The load-bearing capacity of the grid bridge is strong, and high-quality steel wires are optimized and mixed according to mechanical principles. A specially customized welding machine is used for horizontal and vertical cross welding, as well as T-shaped welding of the side and top chord. Each welding point can withstand a tension of 500 kilograms. There are multiple options for surface treatment, such as galvanizing, hot-dip galvanizing, and stainless steel, to ensure the durability and robustness of the product.

Introduction of the product

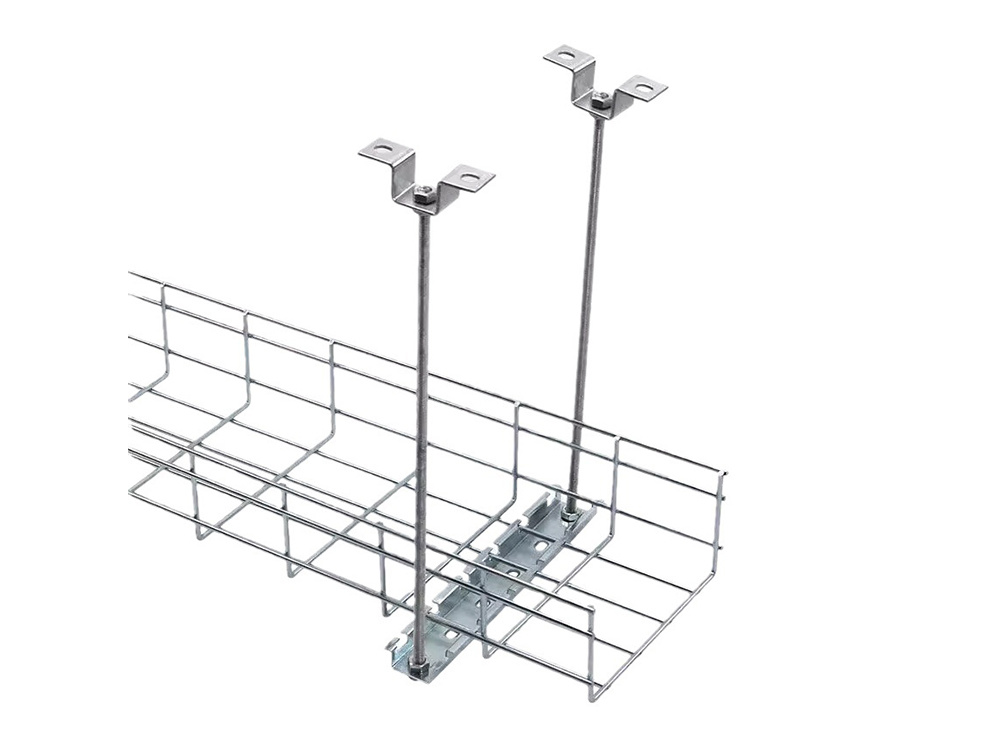

The advantages of grid cable trays include flexible and fast installation, aesthetic appeal, reduced cable procurement costs and energy consumption, simple maintenance, strong load-bearing capacity, and durability. The grid bridge is designed with an open layout, allowing for natural ventilation and heat dissipation of cables. Heat does not accumulate and the temperature inside the bridge does not rise. Therefore, cable performance is optimized, allowing for the use of cables with smaller cross-sectional areas, thereby reducing cable procurement costs and energy consumption. In addition, the installation of grid cable trays is flexible and fast, without the need for customized components such as elbows and tees. They can be made into various forms according to the actual construction situation, greatly reducing installation time. Due to its open design, cables are visible and maintenance and repair work becomes simple, making it easy to identify cables that need to be replaced.

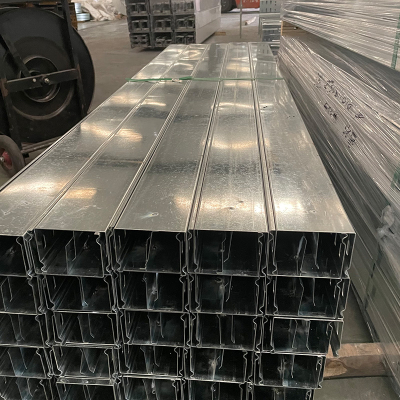

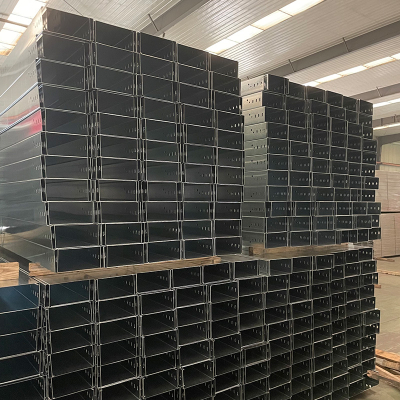

Product type | Ladder Cable Tray/Channel Cable Tray/Perforated Cable Tray | |

| Material | Hot-dip galvanized /stainless steell fireproof spray 7aluminum alloy | |

| Surface Treatment | Pre-Gal/Electro-Gal/Hot dipped galvanized/Powder coated/Polishing | |

| Size | Width | 50-1200mm |

| Side rail height | 25-300mm | |

| Length | 2000mm,3000-6000mm or Customization | |

| Thickness | 0.6-3mm | |

| Steel Thickness (Recommend) | 1.00mm-50*25mm,75*75mm | |

| 1.2mm-100*50mm,150*100mm | ||

| 1.5mm-200*100mm,300*150mm,400*150mm,500*150mm | ||

| 2.0mm-600*200mm,700*200mm | ||

| 2.5mm-800*200mm | ||

| As customer requirements | ||

| Color | As customer requirements | |

| Certification | ISO9001/CCC/CE/UL/CUL | |

| Used | Wiring system,cable management,hoisting system,construction industry and so on | |

| Loading Test | Our wire mesh cable tray meet the standards requirements of IEC61537 and NEMAVE-1 | |

| Non standard specifications are availabe according to customers'requirement | ||

Production process:

QC:

Application:

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a long-term commitment to the cable tray engineering industry, high-quality service material suppliers, the company is located in Liaocheng City, Shandong Province, Liaocheng, “Jiangbei Water City”, “Canal City” reputation, beautiful scenery, convenient transportation, is specialized in cable tray R & D, production, sales and installation of professional manufacturers, adopting the international advanced cable tray manufacturing process, with the current domestic leading level of cable tray one-time forming production line. The company is a professional manufacturer specializing in the research and development, production, sales and installation of cable tray, adopting the international advanced cable tray manufacturing process, with the current domestic leading level of the tray once formed production line. At present, the factory covers an area of 20,000 square meters, with more than 230 employees, the average daily output of about 120 tons, with a number of integrated production lines and many automated equipment. Our factory pursues the business philosophy of “quality as the basis, integrity as a guarantee, management to be effective, innovation and development”, adheres to the business philosophy of “customer-centered”, always seeks for perfection, sincerely returns to the society, and builds a brilliant future for the blue water and the blue sky with excellent products and perfect service.

Production workshop: