Slotted Cable Tray Price

Trough type cable trays can be used for fully enclosed cable laying. It is most suitable for laying control cables for computer cables, communication cables, thermocouple cables, and other high-sensitivity systems. It has good effects on shielding interference of control cables and protecting cables in heavily corrosive environments.

When using trough cable trays and their supports and hangers in corrosive environments, they should be made of corrosion-resistant rigid materials or treated with anti-corrosion measures that meet the requirements of engineering environment and durability.

Introduction of the product:

1. In sections with fire protection requirements, cable trays can be constructed with enclosed or semi enclosed structures by adding fire-resistant or flame-retardant materials such as plates and nets to cable ladders and trays. Measures such as applying fire-resistant coatings to the surfaces of cable trays and their supports and hangers should be taken, and their overall fire resistance performance should meet the requirements of relevant national regulations or standards.

2. Aluminum alloy cable trays should not be used in places with high fire prevention requirements.

3. The selection of width and height for trough cable trays should meet the requirements of filling rate. In general, the filling rate for cable ladders and trays can be 40% to 50% for power cables and 50% to 70% for control cables, with a 10% to 25% engineering development margin reserved.

4. When selecting the load level of the cable tray, the working uniform load of the cable tray should not exceed the rated uniform load of the selected cable tray load level. If the actual span of the support and hanger of the cable tray is not equal to 2m, the working uniform load should meet the requirements.

5. When selecting the bending or leading up and down devices for trough cable trays, the minimum allowable bending radius of the cables inside the cable tray should not be less than.

6. For steel cable trays with a span greater than 6m and aluminum alloy cable trays with a span greater than 2m or load-bearing requirements greater than load level D, strength, stiffness, and stability calculations or experimental verification should be carried out according to engineering conditions.

Production process:

FAQ:

Q1: What varieties of cable trays do you offer?

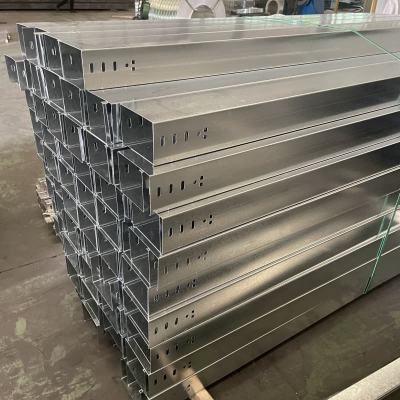

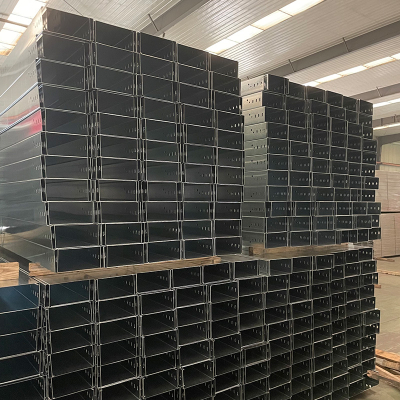

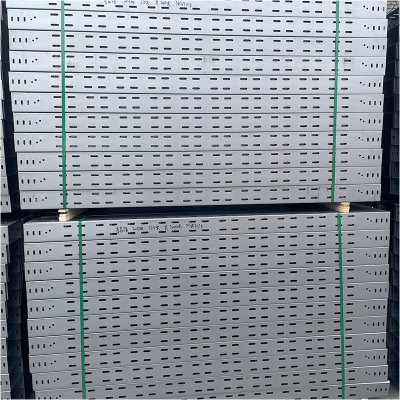

A1: We offer a wide variety of cable trays, including ladder-type, perforated, and solid-bottom trays. Our products are available in different materials (galvanized steel, stainless steel, and aluminum) and surface treatments (hot-dip galvanizing, powder coating, etc.) to suit various project requirements.

Q2: How can I determine the required quantity and specifications of cable trays for my project?

A2: You can provide your project drawings or detailed requirements, and our team will assist you in calculating the required quantity and selecting the appropriate specifications to ensure the best fit for your needs.

Q3: What are the main features of your cable trays?

A3: Our cable trays are durable, corrosion-resistant, and designed for easy installation and maintenance. They are suitable for power distribution, telecommunication systems, and industrial applications, meeting international standards for quality and performance.

Q4: How do you guarantee the quality of your cable trays?

A4: Our cable trays undergo strict production and quality inspection processes, including material testing, dimensional accuracy checks, and surface treatment validation, to ensure they meet industry standards and customer requirements.

Q5: How are the cable trays delivered?

A5: After production and inspection, we pack the cable trays using high-quality materials to prevent damage during transit. We work with reliable logistics partners to arrange efficient transportation and provide tracking information for real-time shipment updates.

For any additional questions or specific inquiries, please contact us. We are here to assist you with all your cable tray needs!

Application:

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a long-term commitment to the cable tray engineering industry, high-quality service material suppliers, the company is located in Liaocheng City, Shandong Province, Liaocheng, “Jiangbei Water City”, “Canal City” reputation, beautiful scenery, convenient transportation, is specialized in cable tray R & D, production, sales and installation of professional manufacturers, adopting the international advanced cable tray manufacturing process, with the current domestic leading level of cable tray one-time forming production line. The company is a professional manufacturer specializing in the research and development, production, sales and installation of cable tray, adopting the international advanced cable tray manufacturing process, with the current domestic leading level of the tray once formed production line. At present, the factory covers an area of 20,000 square meters, with more than 230 employees, the average daily output of about 120 tons, with a number of integrated production lines and many automated equipment. Our factory pursues the business philosophy of “quality as the basis, integrity as a guarantee, management to be effective, innovation and development”, adheres to the business philosophy of “customer-centered”, always seeks for perfection, sincerely returns to the society, and builds a brilliant future for the blue water and the blue sky with excellent products and perfect service.

Production workshop: