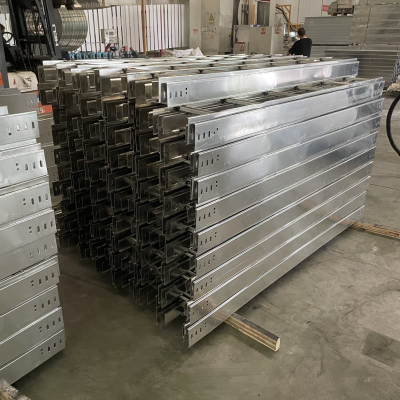

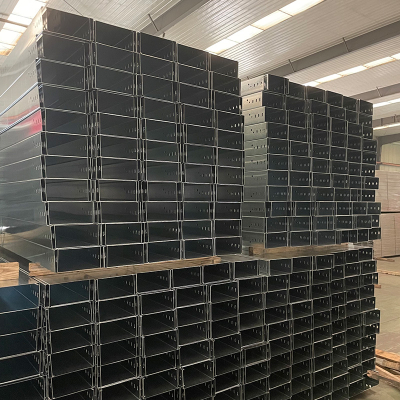

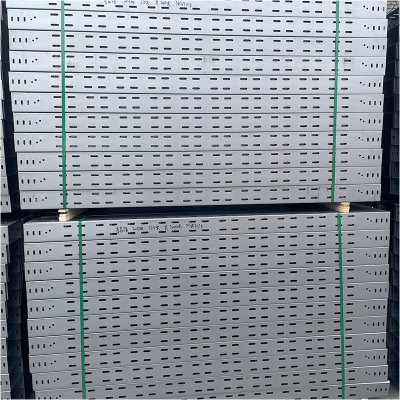

Vci Galvanized Trough Cable Tray Factory

The bridge structure has undergone an advanced VCI bimetallic coating system for floor anti-corrosion, providing exceptional corrosion resistance. Key advantages include:

1.The VCI coating exhibits excellent adhesion to metal substrates, achieving a Class Zero adhesion level;

2.Welded sections are treated with VCI anti-rust primer and topcoat, delivering anti-corrosion performance superior to that of hot-dip galvanized steel and ensuring consistent protection across the entire structure;

3.Outstanding corrosion resistance under various conditions;

4.The VCI coating is non-toxic, odorless, and environmentally friendly, with a high-gloss finish, premium metallic texture, and an aesthetically pleasing appearance;

5.It is fully compatible with organic coatings, allowing additional layers to be applied for enhanced resistance against acidic, alkaline, and other highly corrosive media;

6.As a metallic coating enhanced with high-performance vapor-phase inhibitors, it offers excellent weather resistance, UV stability, and long-term durability without aging;

7.The coating provides cathodic protection and self-healing properties for minor surface damages.

Introduction of the product:

The VCI coating is a type of metallic coating. Through the innovative application of high-performance vapor phase corrosion inhibitor (VCI) technology, it delivers long-lasting anti-corrosion protection to both the coating and the substrate, ensuring durable defense. The primary corrosion resistance mechanism operates as follows:

1.VCI compounds within the coating release VCI molecules, creating a protective VCI atmosphere within the enclosed coating space;

2.The VCI molecules diffuse and migrate to every corner of the enclosed area—including holes, grooves, and other hard-to-reach spots. Even the most vulnerable areas, such as scratches and damaged sections, are protected through this continuous diffusion;

3.VCI molecules accumulate and condense on any metal surface they contact (e.g., hot-dip galvanized layer, zinc powder surface);

4.These molecules dissolve within the electrolyte membrane of the coating and undergo ionization;

5.The resulting VCI ions adsorb onto the metal surface (such as the galvanized layer or zinc powder), forming a passive protective film;

6.VCI molecules in the atmosphere can continuously condense on the metal surface at any time, maintaining the integrity of the protective layer.

Production process:

Application:

The highly corrosion-resistant VCI (Vapor Phase Corrosion Inhibitor) bimetallic composite coating effectively prevents rust formation in coastal and humid environments. The energy-saving metal cable tray, manufactured with this advanced VCI bimetallic coating technology, offers high load-bearing capacity and long-term resistance to salt spray and chemical corrosion. It also provides electrochemical cathodic protection to the metal, effectively preventing pitting corrosion and stress corrosion cracking. As an environmentally friendly and cost-effective solution, this energy-saving cable tray with superior anti-corrosion performance is an optimal choice for coastal applications.

Company Profile:

An outstanding provider of enterprise company materials, Shandong Bolt Electrical Equipment Co., Ltd. has a long history of dedication to the cable tray engineering commercial enterprise business. Personalized add-ons for galvanized cable trays, hot-dip galvanized cable trays, stainless steel cable trays, aluminum alloy cable trays, large-span cable trays, fire-resistant cable trays, trough cable trays, trapezoidal cable trays, self-locking cable trays, porous cable trays, drip problem cable trays, polymer cable trays, fiberglass cable trays, and essentially the best kinds of accessories are among the company's essential products. The most exciting devices and comprehensive specs are found in our company's merchandise. The quality of our products keeps improving, and the specifications are continuously refined, thanks to the attention and information provided by our customers. For a win-win scenario, we are willing to work with all bosses!

Production workshop: