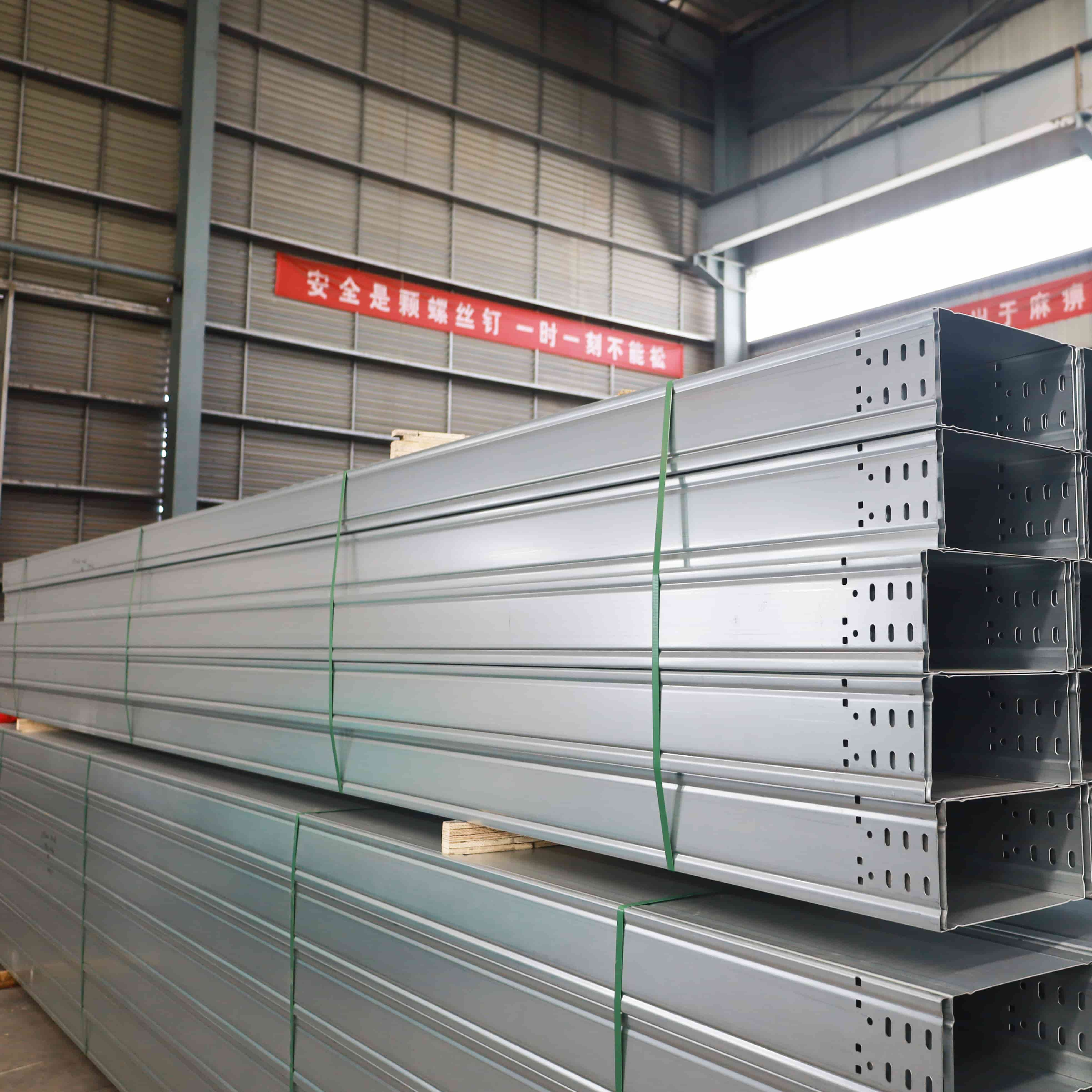

Aluminum Alloy Cable Tray Ladder Type

Advantages of aluminum profile cable tray:

1. Lightweight and High Strength: Aluminum alloy fabric notably reduces the weight of the bridge, making it effortless to transport and install, whilst preserving excessive energy and steady help for cables.

2. Strong corrosion resistance: Aluminum alloy has herbal oxidation resistance, and after treatment, it has greater corrosion resistance, appropriate for humid, salt spray, or acid-base environments, lowering protection costs.

3. Good warmness dissipation: Good thermal conductivity efficaciously dissipates cable heat, avoids overheating problems, and ensures the steadiness and protection of the electricity system.

4. Beautiful and practical: The look is smooth, the structure is simple, and it fits the present day architectural style, bettering the visible impact of the project.

5.Strong load-bearing capacity: Despite being lightweight, it has a giant load-bearing capacity, assembly the necessities for cable laying.

These benefits make aluminum profile cable trays an best preference for current electrical wiring.

Introduction of the product:

Aluminum profile cable trays are extensively used, more often than not mirrored in the following aspects:

1. Industrial environment: such as chemical plants, pharmaceutical factories, etc., due to their correct corrosion resistance, are appropriate for environments with a excessive awareness of chemicals, decreasing air pollution risks.

2. Construction engineering: In business structures such as massive buying centers, workplace buildings, and residential communities, it is used to lift and control cables, which is each lovely and practical.

3. Power facilities: such as substations, strength plants, and aluminum alloy cable trays, their excessive temperature resistance and corrosion resistance make them an perfect desire to make certain the protection and balance of the strength distribution system.

4. Transportation: Provide environment friendly options for cable administration in locations such as subways, railways, and airports to make certain secure and secure operation.

5. Outdoor facilities: such as verbal exchange base stations, outside energy equipment, aluminum alloy cable trays can stand up to a number climate prerequisites and furnish steady cable support.

Production process:

Application:

Aluminum profile cable trays are appreciably used in cable wiring in industrial plants. Due to their lightweight, corrosion resistance, and immoderate reliability, they can meet the requirements of wire routing constructions in industrial manufacturing environments, at the same time as moreover facilitating safety and replacement. Aluminum profile cable trays are significantly used in cable tray constructions in commercial enterprise buildings, which consists of statistics centers, place of work buildings, schools, etc. Its advantages of slight weight, beauty, prolonged lifespan, and impenetrable use have earned it big recognition.

In large sports activities things to do venues, aluminum profile cable trays can meet the desires of low fee and fast installation, imparting sturdy resource for lighting, data transmission, etc.

Aluminum profile cable trays have end up a cornerstone of cutting-edge cable administration systems, specially in industrial, commercial, and infrastructure projects. With a aggregate of durability, corrosion resistance, and light-weight structure, aluminum cable trays are perfect for organizing and defending electrical wiring in a scalable and environment friendly way. For wholesalers and contractors, appreciation the structural, material, and regulatory specs of aluminum cable trays is vital when making bulk purchases.

This article explores the technical elements of wholesale aluminum profile cable trays, overlaying key specifications, manufacturing materials, enterprise standards, set up considerations, and compliance requirements.

1. What Are Aluminum Profile Cable Trays?

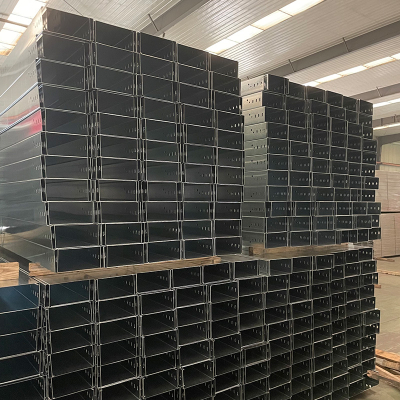

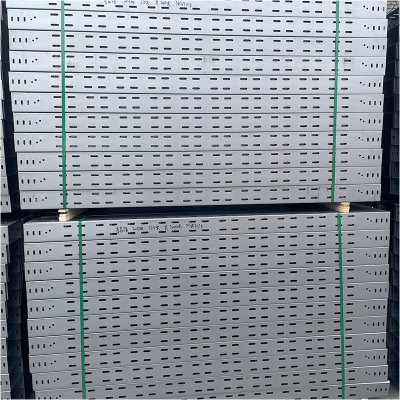

Aluminum profile cable trays are structural systems designed to support, route, and protect electrical cables and wires. They are often manufactured using extruded 6063 or 6061 aluminum alloy profiles, offering a balance of strength, corrosion resistance, and thermal performance. These trays come in a variety of designs, including:

Ladder Type

Solid Bottom

Perforated Type

Trough Type

Wire Mesh (Basket Style)

Each type serves different cable routing and ventilation requirements.

2. Why Choose Aluminum for Cable Tray Systems?

2.1 Material Properties

Weight: ~1/3 the weight of steel trays, reducing structural load and installation effort.

Corrosion Resistance: Naturally resistant to atmospheric and chemical corrosion.

Electrical Conductivity: Aluminum can act as a grounding path if designed per IEC 61537 or NEC Article 392.

Thermal Expansion: Coefficient of expansion is 23.1 µm/m·K, requiring thermal gap planning during installation.

2.2 Common Alloys and Standards

| Alloy | Standard | Typical Use |

|---|---|---|

| 6061-T6 | ASTM B221 | High-strength industrial applications |

| 6063-T5 | ASTM B221 | General-purpose architectural trays |

3. Engineering Specifications for Wholesale Applications

3.1 Load Capacity

Span vs Load: Confirm maximum uniform load at a given span. For instance, a 300 mm wide ladder tray (2.0 mm thickness) typically supports up to 100 kg/m at a 2.5 m span.

Deflection Criteria: Should not exceed L/100 per NEMA VE 1 or IEC 61537.

3.2 Dimensions and Profile Types

Standard widths: 100 mm to 900 mm

Standard heights: 25 mm to 150 mm

Thickness: 1.5 mm to 3.0 mm depending on application

Profile options: C-shaped, U-channel, T-slot aluminum for modular integration

3.3 Surface Finish Options

Mill finish

Anodized (clear or colored)

Powder coated (if aesthetics or environmental exposure require)

4. Installation Guidelines and Regulatory Compliance

4.1 Codes and Standards

IEC 61537 – Requirements for cable tray systems

NEMA VE 1 & VE 2 – American cable tray design and installation

NEC Article 392 – U.S. National Electric Code for cable trays

CSA C22.2 No. 126.1 – Canadian standards for metal cable trays

4.2 Grounding and Bonding

If the tray is used as an equipment grounding conductor (EGC), bonding jumpers are required at tray joints unless a continuous aluminum profile is proven to meet resistance limits (≤ 0.1 ohms across joints).

4.3 Environmental Considerations

Aluminum trays are suitable for:

Indoor & outdoor use

Coastal and humid regions

Chemical processing plants (with anodized coating)

Data centers with EMI-sensitive equipment (with shielding modifications)

5. Key Considerations When Purchasing Wholesale

5.1 Sourcing and Quantity Planning

Minimum Order Quantities (MOQ): Typically start at 100 meters or 500 kg depending on manufacturer

Customization Options: Tray length (usually 2.5 m or 3.0 m per piece), hole pattern, finish, connection accessories

Logistics: Bulk shipments often require full-container load (FCL) planning and stackable packaging design

5.2 Cost Factors

Raw aluminum prices (average ~$2,200/ton in 2025)

Anodizing and finishing costs

Accessory pricing (brackets, splices, fasteners)

Shipping (FOB vs CIF)

6. Common Use Cases

Industrial Factories: Supporting high-voltage cables for machinery

Commercial Buildings: Routing network and control wiring

Infrastructure Projects: Tunnel and bridge installations due to corrosion resistance

Solar Farms: Carrying solar panel connections in corrosive, outdoor environments

7. Frequently Asked Questions (FAQs)

Q1: Are aluminum trays stronger than steel trays?

A: No, aluminum trays are generally lighter and less strong than galvanized or stainless steel trays. However, their corrosion resistance and ease of installation make them ideal for many applications.

Q2: Can aluminum cable trays be used in explosive environments?

A: Yes, if designed with proper grounding and in compliance with ATEX directives or NEC Class I, Division 1 requirements, they can be used in hazardous areas.

Q3: How do I determine the correct tray size?

A: Consider cable fill capacity (usually ≤ 40% of tray cross-section), cable weight, and routing layout. Use sizing tables provided in IEC 61537 or NEMA VE 1 for accurate selection.

Q4: Do aluminum trays require maintenance?

A: Minimal maintenance is required; periodic inspections for corrosion, grounding continuity, and mechanical damage are recommended.

Conclusion and Call to Action

Wholesale aluminum profile cable trays provide a scalable, lightweight, and corrosion-resistant solution for modern cable management systems. With compliance to international standards like IEC 61537 and NEMA VE 1, they are a dependable choice for contractors, distributors, and infrastructure developers.

If you're planning a large-scale project or managing bulk procurement, ensure your specifications align with engineering standards and regional electrical codes.

We offer expert consultation and customization services for aluminum profile cable trays tailored to your project’s needs.

Get in touch today to request a quote, technical drawings, or sample specification documents tailored to your upcoming installation.