Hot Dip Galvanized Large-Span Cable Tray Factory

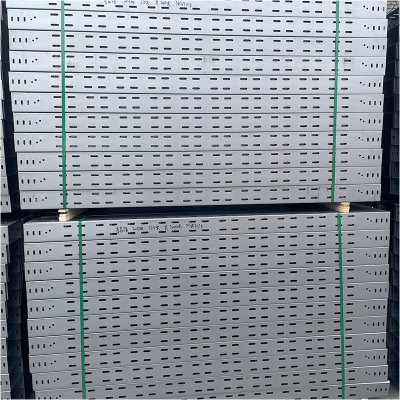

The modular design of galvanized cable trays makes them easy to transport, store, and install. They can quickly complete on-site installation, reducing labor costs and time. Its standardized features and connectivity methods also improve job efficiency and reduce error costs throughout setup.

The galvanized bridge's floor is stunning and colorful, meeting the aesthetic requirements of modern design. In the meantime, its outstanding overall performance in dissipating heat helps the cable function on a daily basis and prolongs its provider life.

The metal and zinc utilized in the hot-dip galvanizing process are renewable, non-toxic materials that no longer provide a long-term risk to the environment. Waste galvanized cable trays can be recycled and reused, decreasing useful resource consumption and waste generation, in line with the idea of sustainable development.

Introduction of the product:

Because its galvanized floor can correctly withstand corrosion in difficult outside settings like rainwater, sunlight, salt spray, etc., galvanized cable trays are frequently used for outdoor cable wiring, such as overhead laying of outdoor cables, lights systems, etc. Galvanized cable trays are suitable for situations like ports, docks, and coastal cable installation because they can effectively tolerate corrosive chemicals like salt spray in coastal environments.

Additionally, galvanized cable trays are frequently utilized in sensible irrigation and temperature control buildings in the agricultural region to protect cables from environmental damage and ensure the system operates as intended. In the discipline of new energy, galvanized cable trays are additionally extensively used for cable laying in wind electricity flora and photovoltaic electricity stations, making sure long-term corrosion resistance of cables in outside environments.

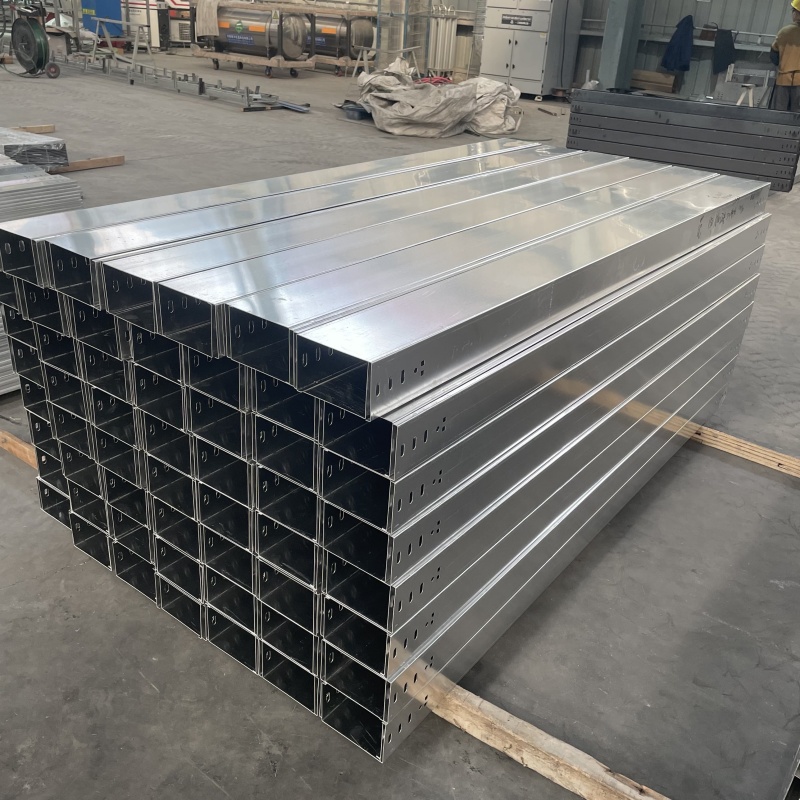

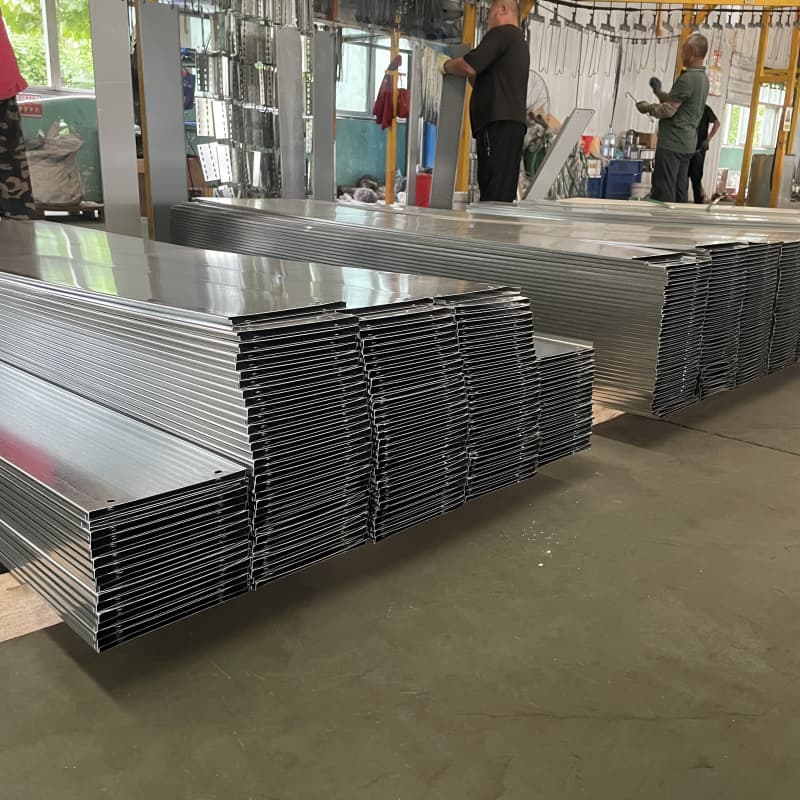

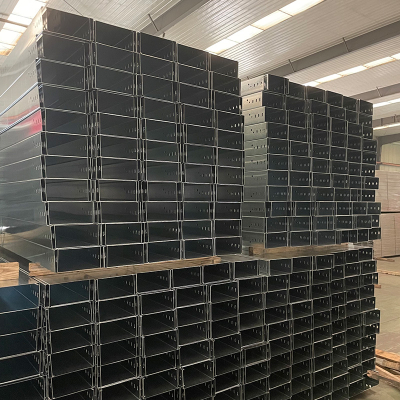

Production process:

Application:

A wide range of industries, including energy engineering, lighting engineering, industrial buildings, residential areas, large public spaces, industrial surroundings, conversation and statistics facilities, and infrastructure projects, employ galvanized cable trays. In both indoor and outdoor settings, galvanized cable trays can provide durable cable laying and administration alternatives.

Galvanized cable trays have become the preferred solution for cable management in numerous industries and locations because of their many advantages, including their longevity, exceptional strength, ease of development and installation, beautiful heat dissipation, environmental safety and recyclability, and wide utility fields.

Company Profile:

For a long time, Shandong Bolt Electrical Equipment Co., Ltd. has been a very good employer. It has a domestically dominant cable tray one-time molding manufacturing line and uses the most environmentally friendly cable tray manufacturing science in the world.

Galvanized, stainless steel, aluminum alloy, fire-resistant, and polymer cable trays are among our standard products. With knowledgeable product designers and administrative staff, our production facility boasts strong technological capabilities. In the drawing and production of cable trays, we have also learned from experts who have been involved in cable tray layout and production for many years, as well as from known applied sciences and experiences both domestically and internationally. The novel form, sensible structure, total specifications, and flexible configuration have created extremely good stipulations for shortening the placing up dimension of the project.

Production workshop: