Wall Mounted Hot-Dip Galvanized Bridge Manufacturer

Selection of cable tray types and varieties:

1. When it is necessary to shield cable networks from electrical interference or guard against external effects (such as corrosive liquids, combustible dust, etc.), a trough type composite anti-corrosion shielding cable tray (with cover) should be used.

2. In severely corrosive settings, employ composite epoxy resin anti-corrosion and flame retardant cable trays. To extend the life of the cable tray and accessories, the support arm and bracket should be made from the same materials. Cover plates should be installed in environments or outdoor areas that are prone to dust collection and require protection.

3. In addition to the conditions listed above, tray type, trough type, step type, glass anti-corrosion and flame-retardant cable trays, or steel ordinary cable trays can be chosen based on the on-site environment and technical specifications. Cover plates should be installed in environments or outdoor areas that are prone to dust collection and require protection.

4. When traversing public passages or outdoor road parts, it is recommended to place padding or pallets at the bottom of the lower steps. When traversing public passages with long spans, the load capacity of the bridge structure can be raised, or a scaffolding can be used based on user needs.

5. Composite cable trays should be used for long spans (>3m).

6. A composite epoxy resin bridge should be chosen for outdoor application.

Introduction of the product

Selection of cable tray specifications:

1. The width and height of the bridge should not exceed the cable filling rate stated in the relevant standards and specifications. Power cables can account for 40-50% of the total, control cables for 50-70%, and an additional 10-25% for structural development.

2. The specifications for various bends and accessories must meet the engineering layout conditions and be suitable with the bridge frame.

3. The support and hanger parameters should be configured in accordance with the bridge frame's specifications, layer count, span, and other factors. And it should meet the load's requirements.

Production process:

FAQ:

Q1: What kinds of cable trays do you offer?

A1: We offer a variety of cable trays, including ladder-type, perforated, and solid-bottomed trays. Our products are available in a variety of materials, including galvanized steel, stainless steel, and aluminum, as well as surface treatments such as hot-dip galvanizing and powder coating, to fulfill the unique requirements of each project.

Q2: How can I establish the number and specs of cable trays for my project?

A2: You can share your project drawings or precise requirements with us, and our experts will help you calculate the required amount and choose the suitable specs to ensure the greatest match for your needs.

Q3: What are the main features of your cable trays?

A3: Our cable trays are designed to be sturdy, corrosion-resistant, and simple to install and maintain. They are perfect for power distribution, telecommunications systems, and industrial applications, and they meet international quality and performance requirements.

Q4: How do you maintain the quality of your cable trays?

A4: Our cable trays go through extensive production and quality inspection processes, such as material testing, dimensional accuracy checks, and surface treatment validation, to ensure they satisfy industry standards and customer specifications.

Q5: How to transport cable trays?

A5: After production and inspection, we pack the cable trays using high-quality materials to prevent damage during transit. We work with reliable logistics partners to arrange efficient transportation and provide tracking information for real-time shipment updates.

For any additional questions or specific inquiries, please contact us. We are here to assist you with all your cable tray needs!

Application:

A cable tray is a bracket that supports and holds cables. Cable trays are commonly used in engineering, as long as cables are laid, cable trays must be used. As a supporting project of wiring engineering, the design and selection process of cable trays should be based on the type and quantity of customer needs, and the appropriate cable trays should be selected reasonably. Cable trays have the characteristics of wide variety, wide application, high strength, light structure, low cost, simple construction, flexible wiring, standard installation, and beautiful appearance.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a long-standing supplier of high-quality service materials for the cable tray engineering industry. The company is situated in Liaocheng City, Shandong Province, Liaocheng, which is known as "Jiangbei Water City" and "Canal City." It is specialized in cable tray R&D, production, sales, and installation of professional manufacturers, adopting the international advanced cable tray manufacturing process, and currently has the highest level of cable tray one-time forming production line. The company is a professional manufacturer that specializes in cable tray research and development, production, sales, and installation. It uses an international sophisticated cable tray manufacturing process, and its production line is currently at the top level in the country. At present, the factory covers an area of 20,000 square meters, with more than 230 employees, the average daily output of about 120 tons, with a number of integrated production lines and many automated equipment. Our factory pursues the business philosophy of “quality as the basis, integrity as a guarantee, management to be effective, innovation and development”, adheres to the business philosophy of “customer-centered”, always seeks for perfection, sincerely returns to the society, and builds a brilliant future for the blue water and the blue sky with excellent products and perfect service.

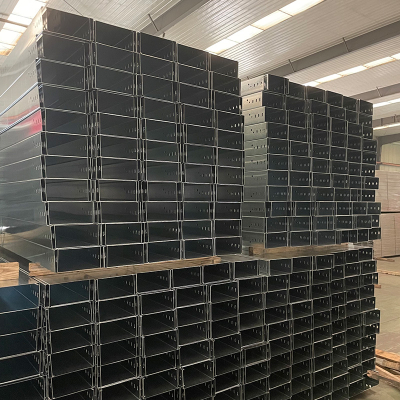

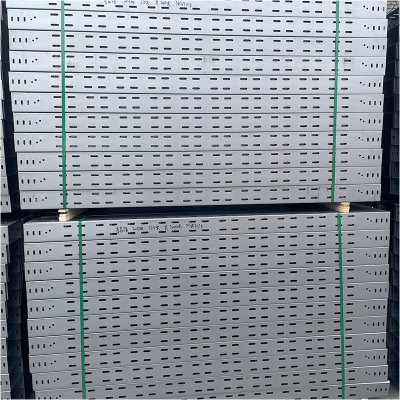

Workshop Show: