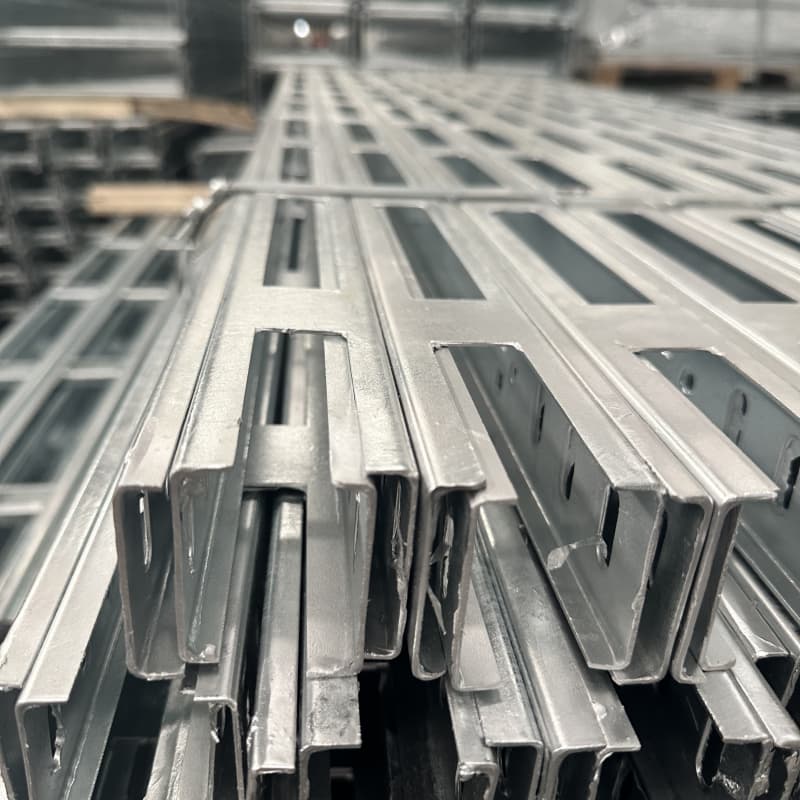

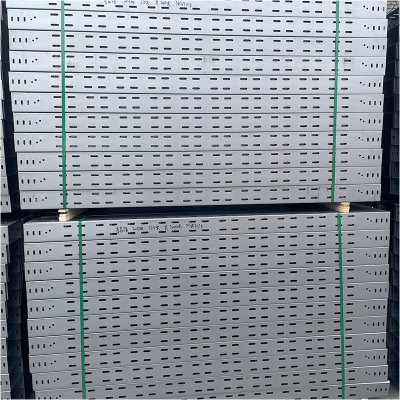

Hot-Dip Galvanized Cable Trays Wholesale

The core gain of hot-dip galvanized cable trays lies in their awesome anti-corrosion performance. The hot-dip galvanizing manner includes immersing the bridge into molten zinc solution, and through chemical reactions and bodily bonding between the zinc answer and the floor of the bridge, forming a dense layer of zinc iron alloy and pure zinc. This coating can efficiently isolate the bridge substrate from direct contact with the exterior environment, preventing the corrosion of the bridge by means of oxygen, moisture, and different corrosive media in the air. Compared to standard portray or electroplating methods, hot-dip zinc coating has enhanced adhesion and longer corrosion resistance. Even in harsh industrial environments or coastal areas, it can hold long-term secure anti-corrosion effect, notably extending the provider existence of cable trays.

Introduction of the product:

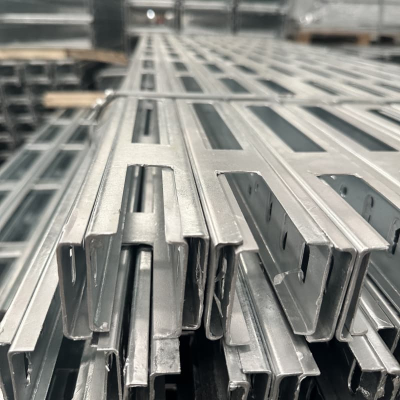

Hot dip galvanized cable trays have more than one advantages:

1. Excellent anti-corrosion performance: Hot dip galvanizing cure varieties a thick zinc layer on the floor of the bridge, efficaciously keeping apart oxygen and moisture, stopping corrosion, in particular appropriate for corrosive environments such as humidity and chemical plants.

2. Strong durability: The thick zinc layer gives long-term protection, resists harsh environmental conditions, has a carrier existence of countless decades, and has low upkeep costs.

3. Good mechanical performance: Maintain the unique mechanical electricity of the bridge, the zinc layer has durability and put on resistance, and can stand up to mild influences and wear.

4. Economy and environmental friendliness: Although the preliminary value is high, sturdiness reduces preservation requirements, and in the lengthy run, it is economical; The zinc layer is recyclable and meets environmental requirements.

5. Other advantages: It has self-healing function, excessive temperature resistance, UV resistance, lovely appearance, robust adaptability, and is appropriate for more than a few cable administration scenarios.

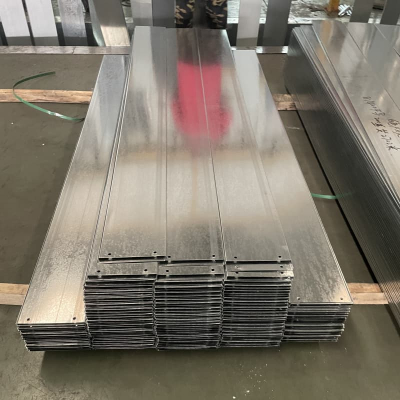

Production process:

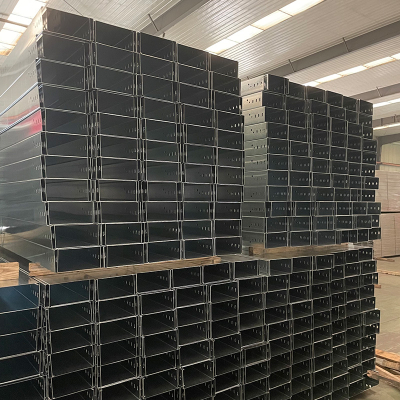

Application:

Hot dip galvanized cable trays can correctly face up to wind, rain, ultraviolet radiation, and salt corrosion, and are appropriate for road lighting fixtures systems, highways, railway lines, as properly as seaports, docks, etc. In environments with corrosive gases and excessive humidity such as chemical plants, refineries, and metallurgical plants, hot-dip galvanized cable trays furnish precise safety for cables.

In high-voltage transmission lines, substations, tunnels, underground garages, and different places, hot-dip galvanized cable trays make sure the steadiness and protection of cables. In municipal infrastructure such as bridges and utility poles, as nicely as in mining and mining industries, hot-dip galvanized cable trays are appropriate for long-term use and low protection needs.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a notable organisation material corporation dedicated to the cable tray engineering industrial agency organisation for a extended time. It adopts internationally most surroundings pleasant cable tray manufacturing science and has a domestically predominant cable tray one-time molding manufacturing line.

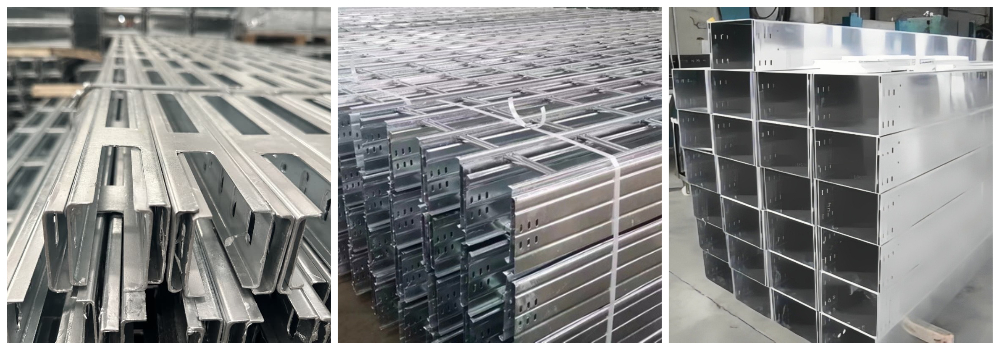

Our quintessential merchandise consist of galvanized cable trays, stainless metal cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our manufacturing unit has sturdy technical strength, with professional product designers and administration personnel. In the plan and manufacturing of cable trays, we have in addition absorbed everyday utilized sciences and experiences at domestic and abroad, and have educating from professional authorities who have participated in cable tray sketch and manufacturing for many years. The factors of the cable tray have been serialized and standardized. The novel form, clever structure, whole specifications, and bendy configuration have created pinnacle notch stipulations for shortening the setting up dimension of the project.

Production workshop: