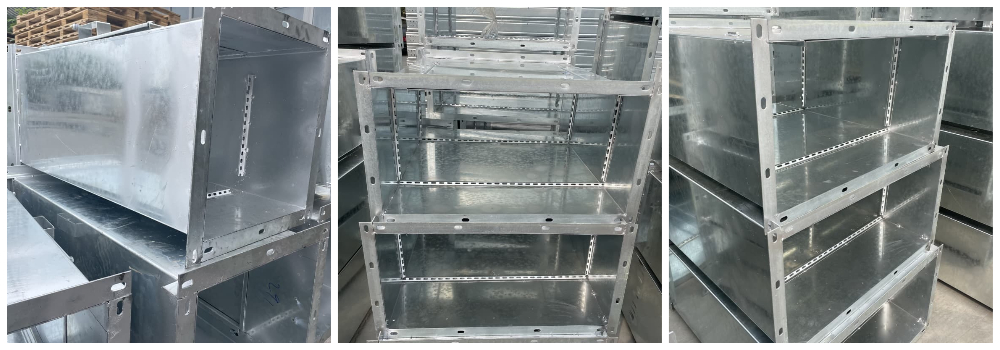

Vertical Shaft Galvanized Cable Tray Manufacturer

In electrical systems, vertical shaft cable trays are an essential component, and their design and commitment like to assume a few things.

The lightweight design of the vertical shaft cable tray significantly lowers improvement costs, minimizes vertical shaft loads, and has excellent thermal conductivity, which may effectively improve warmth dissipation effectiveness and prolong cable life. It also uses low-energy production technology, complies with inexperienced installation regulations, and has exceptional strength and corrosion resistance, which prolongs the provider's life and lowers maintenance expenses.

Introduction of the product:

It is crucial to make assumptions regarding the technical requirements and on-site environment when researching a vertical shaft cable tray. A particular type of cable tray should be chosen if preventing electrical interference or protecting against external environmental influences is required. Positive technological solutions must be used during the setup process, such as placing and laying out, adding bolts or embedding iron elements, etc., to ensure the stability and safety of the bridge.

In electrical systems, vertical shaft cable trays are essential. They are extremely good at increasing efficiency, reducing electrical energy consumption, and prolonging provider life because of their lightweight design, beautiful thermal conductivity, and low-energy production process.When identifying on and installing, it is essential to assume about the special nation of affairs to make positive its steadiness and safety.

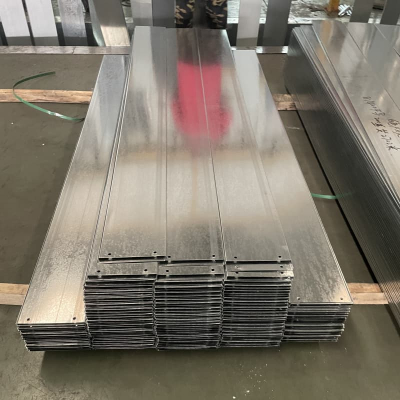

Production process:

Shipping Process:

For many years, we have been a manufacturer with a focus on producing cable trays. We have a fantastic inspection team, a skilled manufacturing team, and an experienced structure team to ensure that every customer may customize products to suit their demands.

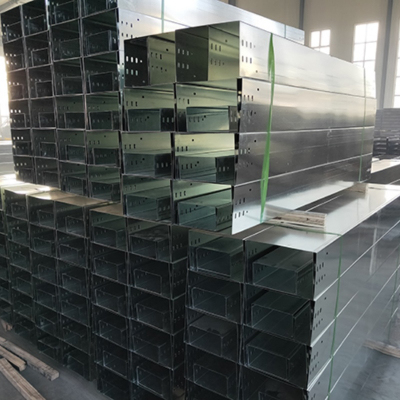

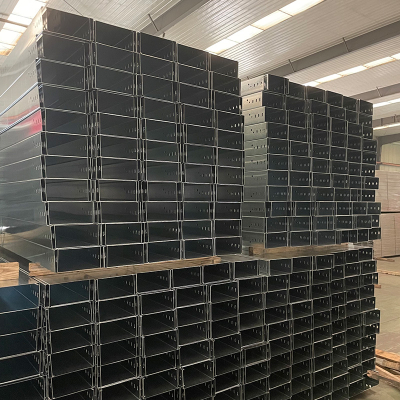

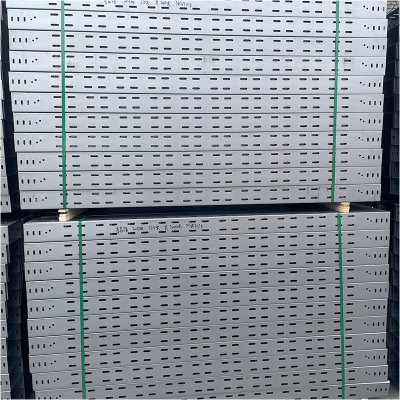

Stainless steel cable trays, galvanized cable trays, aluminum alloy cable trays, trapezoidal cable trays, perforated cable trays, metal wire mesh cable trays, and more are among the company's wide range of goods. Fire-resistant bridge trays, hot-dip galvanized bridge trays, painted bridge trays, colored metal bridge trays, and other similar methods are examples of ground repair procedures for bridges.

Application:

The following are the primary components of vertical shaft cable trays:

Bridge frame made of steel:

Cold rolled metallic plate: Very affordable, great for typical indoor settings, needs flooring therapy to avoid corrosion.

Hot dip galvanized steel plate: Excellent for areas with high humidity or out-of-doors, it resists corrosion well.

Excellent resistance to corrosion, stainless steel is ideal for corrosive areas like beaches and chemical factories.

Bridges made of aluminum alloy are lightweight, corrosion-resistant, attractive for both indoor and outdoor settings, and have unique decorative and heat-dissipating qualities. They are also readily installable.

Fiberglass bridge frame: composed of glass fiber reinforced plastic, it has excellent furnace and corrosion resistance, is beautiful for robust corrosive conditions, and performs well as insulation.

Spray-painted bridge: Typically used indoors or in regular garden settings, the flooring is treated with a spray coating to increase corrosion resistance and local weather resistance.

Bridges made of composite materials, like polyurethane, are beautiful for settings with strong electromagnetic interference or moderate corrosiveness since they are corrosion-resistant, acquire aging resistance, and have remarkable insulating qualities.

It is crucial to make thorough assumptions regarding aspects like the usage environment, load requirements, corrosion resistance, and budget when researching materials.

Company Profile:

The cable tray engineering sector is the focus of Shandong Bolte Electrical Equipment Co., Ltd., a super employer fabric business agency organization. The company, which is based in Liaocheng, Shandong Province, focuses on cable tray research, development, manufacturing, sales, and setup. It has a domestically developed one-time molding cable tray manufacturing line that uses the best cable tray manufacturing technologies available worldwide. The production facility currently occupies 20,000 square meters, has over 230 employees, and uses a daily output of over 120 tons to produce an average day. It has multiple built-in production traces and a few special computerized pieces of equipment. Galvanized trays, stainless metallic trays, aluminum alloy trays, fireproof trays, and polymer trays are among the many types of cable trays that the industrial employer-employer organization usually offers. Following the company's philosophy of "quality as the foundation, integrity as the guarantee, immoderate excellent management, and progressive development," as well as the enterprise business cause of "customer-centric," the manufacturing unit constantly aims for perfection, merely provides as much to society as possible as soon as possible, and aspires to create a remarkable future for blue skies and clear waters with surprisingly appropriate products and first-rate services.

Production workshop: